Tetrataenite Magnets

June 19, 2023

Iron is, by

mass, the

most common element on Earth, but iron

oxidizes (

rusts) rapidly, and

metallic iron is rarely found on

Earth's surface. Pure iron is a very

soft material with about the same

flexibility as

aluminum. However, addition of less than two percent

carbon produces

carbon steel, and some carbon steels are up to 1000 times

harder than pure iron. Another important

property of iron and some iron

alloys is their

ferromagnetism. Pure α-iron, the

room temperature body-centered cubic (BCC) crystal form of iron, is

magnetic below its

Curie temperature of 770

°C (1,420

°F; 1,040

K), and it can be made into a

permanent magnet by cooling through its Curie temperature in the presence of a

magnetic field.

Some iron alloys, in particular

Alnico 5, an alloy of iron (51 at-%), aluminum (8 at-%),

nickel (14 at-%),

cobalt (24 at-%), and

copper (3 at-%), were commonly used as permanent magnets in the

mid-20th century. One popular use was as

loudspeaker magnets. Such magnets were replaced by the superior

rare-earth magnets in the

1970s. An important

figure of merit of a magnet is its

maximum energy product, the maximal value of the

product of

magnetic induction (B) and

applied magnetic field (H) on its

hysteresis curve. The maximum energy product of Alnico 5 is 5.5 mega-

gauss-

oersted (MGOe, 43.8 k

J/

m3), while that of most

NdFeB rare earth magnets is greater than 60 MGOe (~500 kJ/m

3).

As I've written in several previous articles (including

Rare Earths from Coal Waste, April 18, 2022,

Rare Earth Metals from Fly Ash, July 7, 2016, and

Materials Supply Chain, July 14, 2014), most rare earth

mining and

refining is in

China. China has a near

monopoly on

global production, producing an estimated 60% of the world's rare earths in 2021, as compared with the 15% of the

United States.[1]

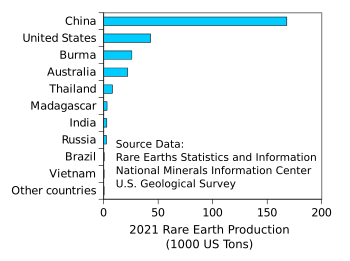

Estimated rare earth production by country in 2021.

China produced 168,000 US tons of rare earth oxide equivalent in 2021, up from 140,000 the previous year.

(Chart created using Gnumeric from data in ref. 2.[2] Click for larger image.)

A non-rare earth permanent magnet would be welcome, especially one made from

inexpensive elements such as iron.

Laboratory synthesis of an unique iron-nickel alloy with promising magnetic properties was announced at the end of 2022 in an

open access paper in

Advanced Science.[2-6] The alloy,

tetrataenite, is found in

meteorites, but rarely found in

nature. It was thought that it could be formed only by a very slow cooling process, estimated to be a few

degrees per million

years, that allowed

diffusion of

atoms into its

L10 layered crystal structure. Prior laboratory synthesis was achieved by

irradiation by

neutrons or

electrons that nudges its atoms into place.

A specimen of tetrataenite, recovered from Zacatecas, Mexico. This is a portion of an H5 chondrite meteor that fell on December 15, 1978. Its size is 2.7x2.0x2.0 centimeters. The tetrataenite crystals appear as silvery patches.

(Wikimedia Commons image by Robert M. Lavinsky.)

The 2022 study, by

materials scientists from the

Istituto Italiano di Tecnologia (Genova, Italy), the

Austrian Academy of Sciences (Leoben, Austria), the

Montanuniversität Leoben (Leoben, Austria), and the

University of Cambridge (Cambridge, UK) found that a small addition of

phosphorus allowed creation of tetrataenite by usual

smelting techniques.[2-6] Tetrataenite can be made permanently magnetic with a high

coercivity that's essential for maintaining a permanently magnetic state. It's

theoretical magnetic energy product is greater than 42 MGOe (335 kJ/m

3), nearly on par with rare earth magnets.[7] However, all theoretical predictions should be taken with

a grain of phosphorus until

experimentally proven.

The

research paper begins with a nice summary of the

prior art with information from a review by Wasilewski.[8] This is summarized in the following table.

Global demand for rare earth magnets is estimated to reach $37 billion by 2027.[6] Aside from China's putative control of the rare earth market, there are

environmental problems as well. Vast quantities of

ore need to be mined to extract small quantities of these elements.[4] Furthermore, the subsequent processing of the ore is environmentally

hazardous.[6] The tetrataenite research team was not intentionally on a quest to synthesize this material. They were doing research on the mechanical properties of glassy Fe-Ni-P-B alloys when they discovered dendrites in their specimens.[4-5] Careful measurements using

X-ray diffraction and

transmission electron microscopy revealed the L10 tetrataenite crystal phase.[4-5]

In their experiments, the alloying elements were

cast at 1123 K in copper

molds and then rapidly cooled at a rate of 10-10

4 K/sec.[2,5] Adjustment of the element

ratios showed that the rapid creation of the L10 phase was caused by the phosphorus.[5] Rods cast with a larger diameter, and therefore at a lower cooling rate, had a smaller

volume fraction of the dedritic tetrataenite.[2] The L10 phase had

lattice constants of a = 0.255±0.001 nm, and c = 0.363±0.001 nm.[2]

scanning electron micrograph of a lateral section of a 1 mm diameter rod of Fe50Ni30P13C7 showing tetrataenite dendrites in an alloy matrix.

(Fig. 1b of ref. 2, licensed under a Creative Commons License.)

Says study

author and

postdoctoral research associate at the University of Cambridge,

Yurii Ivanov, "The presence of phosphorus seems to be critical in permitting formation of tetrataenite without such treatments as neutron irradiation."[5] The role of phosphorous is to stabilize

vacancies in the

crystal lattice and accelerate atomic mobility.[2].

Calculations indicate that the atomic mobility at 573 K is accelerated by a factor of more than 10,000 by the addition of 1 at-% P.[2]

A

patent application has been filed, but the study authors did not attempt to create or characterize permanent magnets from their material.[2,4] Some experts see no prospect of these alloys replacing rare-earths in any permanent magnet application.[5] The Cambridge researchers agree that this alloy might not match high-performance neodymium-based magnets.[5] Says study author and

professor of

materials science at Cambridge,

Lindsay Greer,

"The analogy here would be that we have shown we can make a brick - a piece of tetrataenite - but not yet a house - a magnet."[5]

The research was

funded in part by the

European Research Council and the

Austrian Science Fund.[4]

References:

- Rare Earths Statistics and Information, National Minerals Information Center, U.S. Geological Survey, 2022.

- Yurii P. Ivanov, Baran Sarac, Sergey V. Ketov, Jürgen Eckert, and Lindsay A. Greer, "Direct Formation of Hard‐Magnetic Tetrataenite in Bulk Alloy Castings," Advanced Science, vol. 10, no. 1 (October 25, 2022), Article no. 2204315, doi:10.1002/advs.202204315. This is an open access article with a PDF file here.

- Laura H. Lewis, Ian J. Mcdonald, Sahar Keshavarz, and R. William McCallum, "Method of tetratenite production and system therefor," US Patent No. 11,462,358, October 4, 2022.

- New approach to 'cosmic magnet' manufacturing could reduce reliance on rare earths in low-carbon technologies, University of Cambridge Press Release, October 25, 2022.

- Sarah Wells, "Making Cosmic Magnets on Earth," Physics, vol. 15, no. 182 (November 23, 2022).

- Tanner Stening, "Accelerating the Production of Tetrataenite as Alternative to Rare-Earth Magnets," Northeastern University Press Release, October 7, 2022.

- E. Dos Santos, J. Gattacceca, P. Rochette, G. Fillion, and R.B. Scorzelli, "Kinetics of tetrataenite disordering," Journal of Magnetism and Magnetic Materials, vol. 375 (February 1, 2015), pp. 234-241, https://doi.org/10.1016/j.jmmm.2014.09.051.

- Peter Wasilewski, "Magnetic characterization of the new magnetic mineral tetrataenite and its contrast with isochemical taenite," Physics of the Earth and Planetary Interiors, vol. 52, no. 1-2 (October, 1988), pp. 150-158, https://doi.org/10.1016/0031-9201(88)90063-5.

Linked Keywords: Iron; mass; abundance of the chemical elements; most common element on Earth; oxide; oxidizes; rusts; metal; metallic; lithosphere; Earth's surface; ductility; soft; material; deflection (engineering); flexibility; aluminum; carbon; carbon steel; hardness; harder; physical property; alloy; ferromagnetism; room temperature (cientific use); body-centered cubic (BCC) crystal; magnetic; Curie temperature; Celsius; °C; Fahrenheit; °F; kelvin; permanent magnet; magnetic field; Alnico 5; nickel; cobalt; copper; mid-20th century; loudspeaker; rare-earth magnet; 1970s; figure of merit; maximum energy product; multiplication; product; magnetic induction (B); applied magnetic field (H); hysteresis curve; gauss (unit); oersted; joule; cubic meter; neodymium magnet; NdFeB; Rare Earths from Coal Waste; Rare Earth Metals from Fly Ash; Materials Supply Chain; mining; extractive metallurgy; refining; China; monopoly; world economy; global production; United States; 2021 World Rare Earth Production (estimated); rare earth element; mining; production; country; US tons; oxide; Gnumeric; cost; inexpensive; chemical element; laboratory; chemical synthesis; open-access journal; open access paper; Advanced Science; tetrataenite; meteorite; nature; Celsius; degrees; year; diffusion; atom; tetragonal crystal system; L10 layered crystal structure; irradiation; neutron; electron; Zacatecas, Mexico; H5 chondrite meteor; centimeter; crystal; silvery; Wikimedia Commons; Robert M. Lavinsky; materials science; materials scientist; Istituto Italiano di Tecnologia (Genova, Italy); Austrian Academy of Sciences (Leoben, Austria); Montanuniversität Leoben (Leoben, Austria); University of Cambridge (Cambridge, UK); phosphorus; smelting; coercivity; theory; theoretical; a grain of salt; experiment; experimentally; scientific journal; research paper; prior art; redox; oxidation and reduction; molecular beam epitaxy; diffusionless transformation; martensitic transformation; high pressure; torsion (mechanics); annealing (metallurgy); amorphous metal; glassy ribbon; rolling (metalworking); cold rolling; milling (grinding); melt spinning; melt-spun ribbon; nitriding; nanoparticle; nanopowder; environment (biophysical); environmental; ore; hazardous waste; X-ray crystallography; X-ray diffraction; transmission electron microscopy; casting; cast; mold; ratio; volume fraction; lattice constant; scanning electron microscope; scanning electron micrograph; diameter; cylinder (geometry); rod; dendrite (metal); alloy; composite material; matrix; Creative Commons License; author; postdoctoral research associate; Yurii Ivanov; vacancy defect; crystal structure; crystal lattice; calculation; patent application; professor; Lindsay Greer; analogy; brick; house; funding of science; funded; European Research Council; Austrian Science Fund.