Granular Capillarity

June 19, 2017

There are assembly

toys for

children, such as

Lego, but the first

construction materials used by children are typically

snow and

mud. Although much of the world is devoid of snow, even in the

local cold season, every child has access to mud. Nearly 10,000 years ago, our

ancestors didn't just play with mud, they used mud as

adobe to build their

houses. The major constituents of adobe, which make about 85% of this material, are

silt and

sand, both

granular materials.

Chefs in training.

Portion of an 1873 oil on canvas painting entitled, "Mud Pies," by Ludwig Knaus (1829–1910).

This painting now resides at the Walters Art Museum, Baltimore, Maryland.

(Via Wikimedia Commons.)

An understanding of granular materials is good for more than making better mud pies and adobe houses.

Pharmaceutical powders are made into

tablets, and granular materials such as

seeds,

grains,

flour, and

cement must be stored and

transported. The

physics of granular materials has become a popular topic in the last few

decades, with more than 3,000 physics

papers having the word, "granular," in the

abstract posted on

arXiv from 2000 to the present.

A few prominent

Physicists have investigated the properties of granular materials over the

centuries.

Faraday (1791-1867), while notable for his work on

electricity and

magnetism, also discovered the

convective instability of powder to vertical motion in a

vibrated container.

Reynolds (1842-1912) discovered

dilatancy, the tendency for compacted granular material to expand in

volume when it is

sheared.[1-2]

As anyone who has needed to pour powder through a

funnel has noticed,

jamming is the most annoying feature of granular materials. Jamming occurs because the particles are prevented from

flowing past each other since they are held in place by

chains of force that lock them against the sides of the funnel. As shown in the figure, the

weight of an individual particle is carried by many, but not all, of the underlying particles.

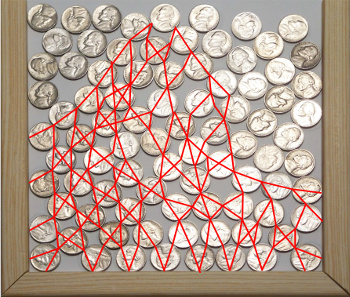

Force chain of stress in a planar granular medium consisting of US nickel coins in a frame of eight inch width.

This is the stress distributed from one of the topmost coins.

(Illustration by the author, via Wikimedia Commons.)

Granular materials exhibit quite a number of unusual properties, the most interesting of which is possibly the

Brazil nut effect, the tendency for large

nuts to move to the top of a

container of mixed nuts after

shaking. This

phenomenon, of course, extends beyond mixed nuts in their can, and it happens in any vertically-shaken, dry, granular

mixture of large and small

particles.[3]

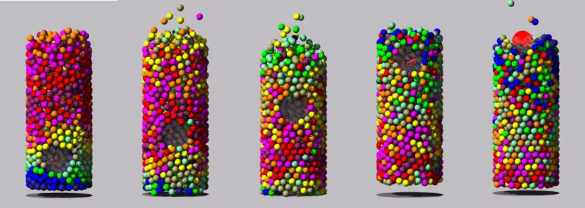

Screenshots of a simulation of the Brazil nut effect. Vibration in the vertical direction causes the large object to rise in a sea of smaller objects. (Used with permission from the Granular Dynamics Update Web Site of Prof. Derek C. Richardson of the University of Maryland - College Park. For further information, see ref. 3)]

Another granular phenomenon that I described in an

earlier article (Sand Dunes, February 14, 2012) is

singing sand, the loud

sound made when

desert sand dunes avalanche or slump as a result of

wind action or human trespass. Desert singing sands produce

low frequency sound, but some dry

beach sands are known to make

high frequency sound when they're walked upon. There is no precise understanding of the mechanism for this, but the sound might arise from a

stick-slip friction between rubbing grains.[4]

A granular material effect that's simply produced in the

laboratory is the

segregation of granular mixtures of different materials as they are poured. This effect, which arises from the combination of

friction and

triboelectricity, can be observed in a

mixture of two different colors of "art sand," found in

craft stores, when they are mixed in a shaker and then poured.[5]

Shaking causes

electrons to be stripped away from the particles by friction, with some of the

charge being lost to the mixing container.[5] The material difference between the particles allows an excess charge to develop on one of the materials, so pouring from the charged container results in a different

repulsive force for the materials that causes "unmixing" of the mixture.[5]

One other granular phenomenon, granular

capillarity, is the topic of a recent

paper in

Physical Review Letters.[6-8] Granular capillarity is the ascent of particles in a narrow

tube when it's inserted into a bed of vibrating granular material, just as a

liquid will rise in a thin tube. This study was a particle-based

simulation by physicists from the

University of Shanghai for Science and Technology (Shanghai, China), the

Friedrich-Alexander-Universität Erlangen-Nürnberg (Erlangen, Germany), and the

University of Cologne (Cologne, Germany). It's interesting to note that one of

Einstein's first published papers was about capillarity.[9]

Liquid capillarity is caused by the attractive forces between the liquid and the tube wall, and it allows

sponges to

absorb water and the lifting water to the tops of

trees. If a tube is dipped into a granular material, nothing will happen. However, if the tube is shaken, the granular material will rise in it. The mystery is why this would happen, since there's not enough attraction between the granular particles and the tube wall to counteract

gravity. Also, the attraction between the

molecules in the liquid hold the liquid together while it rises in the tube, but no such force keeps the granular material together.[8] A vibration of just a few particle

diameters at a few

hertz will result in granular capillarity.[8]

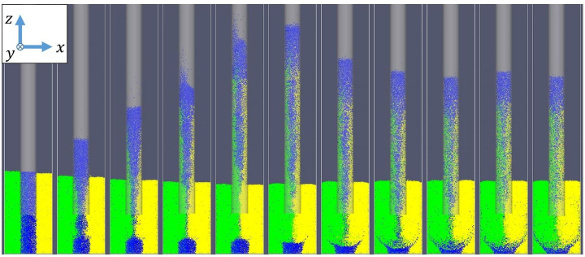

Ascent of particles into a tube by granular capillarity. The granular material rises to a terminal vertical level. (University of Cologne image by Fengxian Fan, Eric Parteli, and Thorsten Pöschel.)

Through use of

discrete element method numerical simulations, the

research team showed that granular capillarity is caused by

convection of the granular material in the container.[6-8] In their simulations, they considered a

rectangular container that was partially filled with

spherical particles about 0.6

millimeter in diameter. A

cylindrical tube of 8 millimeter diameter was inserted into the particles.[7] The

calculations considered the

trajectory of every particle, including the ones outside the tube. This allowed tracking of the

velocity and trajectory of all particles.[8]

Vibrating the tube up and down in the simulation caused the particles to rise about 5

centimeter. When the container walls were made

frictionless, the particles did not rise at all, indicating that convective motion, as in the Brazil nut effect, was the mechanism for the capillarity.[7] This convective motion causes lateral transport of the particles, and this leads to an upward

pressure on the base of the granular column, causing the column to rise.[8]

The speed and height of the granular material's rise in the tube was found to depend on the tube diameter. The terminal height was found to be

inversely related to the tube diameter for large

ratios of the tube to particle diameter.[7] This inverse

functionality is the same found in liquid capillarity.[8] At tube diameters just a few times larger than the particle diameter,

linear behavior is observed.[6] The results hold whether the tube or the container is shaken, and this effect might have

industrial applications.[8]

References:

- Heinrich Jaeger, "An Introduction to Granular Physics," James Franck Institute, University of Chicago Web Site.

- Heinrich M. Jaeger, Sidney R. Nagel, and Robert P. Behringer, "The Physics of Granular Materials," Physics Today, vol. 49, no. 4( April. 1996). pp. 32-38, doi: http://dx.doi.org/10.1063/1.881494. A PDF file can be found here.

- Soko Matsumura, Derek C. Richardson, Patrick Michel, Stephen R. Schwartz, and Ronald-Louis Ballouz, "The Brazil nut effect and its application to asteroids," Mon. Not. R. Astron. Soc., vol. 443, no. 4 (October 1, 2014), pp. 3368-3380. A PDF file is available here, and also at arXiv.

- Vincent Gibiat, Eric Plaza and Pierre De Guibert, "Acoustic emission before avalanches in granular media," arXiv, June 20, 2009.

- Amit Mehrotra, Fernando J. Muzzio, and Troy Shinbrot, "Spontaneous Separation of Charged Grains," Phys. Rev. Lett., vol. 99, no. 5 (August 3, 2007), Document no. 058001, DOI:https://doi.org/10.1103/PhysRevLett.99.058001.

- Fengxian Fan, Eric J. R. Parteli, and Thorsten Pöschel, "Origin of Granular Capillarity Revealed by Particle-Based Simulations," Phys. Rev. Lett., vol. 118, no. 21 (May 23, 2017), Document no. 218001, DOI:https://doi.org/10.1103/PhysRevLett.118.218001.

- Michael Schirber, " Synopsis: Capillary Effect in Grains Explained, Physics, May 23, 2017.

- Physicists Discover Mechanism Behind Granular Capillary Effect, University of Cologne Press Release, May 24, 2017.

Press Release in German.

- Albert Einstein, "Folgerungen aus den Capillaritätserscheinungen," Annalen der Physik, vol. 309, no. 3 (1901), pp. 513-523.

Permanent Link to this article

Linked Keywords: Toy; child; children; Lego; construction; material; snow; mud; winter; cold season; ancestor; adobe; house; silt; sand; granular material; oil on canvas painting; Ludwig Knaus (1829–1910); Walters Art Museum; Baltimore; Maryland; Wikimedia Commons; pharmaceutical; powder; tablet; seed; food grain; flour; cement; transport; physics; decade; scientific literature; paper; abstract; arXiv; physicist; century; Faraday (1791-1867); electricity; magnetism; convective instability; acoustics; vibrate; container; Reynolds (1842-1912); dilatancy (granular material); volume; shear stress; sheared; funnel; jamming (physics); fluid dynamics; flow; force chain; weight; stress (mechanics)2; planar; granular medium; nickel (United States coin); nickel coin; Brazil nut effect; nut; container; vibration; shaking; phenomenon; mixture; particle; screenshot; computer simulation; vertical direction; Prof. Derek C. Richardson; University of Maryland - College Park; singing sand; sound; desert; sand dune; avalanche; wind; low frequency sound; beach; high frequency sound; stick-slip friction; laboratory; segregation (materials science); friction; triboelectric effect; triboelectricity; craft store; electron; electric charge; Coulomb's law; repulsive force; capillary action; capillarity; scientific literature; paper; Physical Review Letters; tube; liquid; University of Shanghai for Science and Technology (Shanghai, China); Friedrich-Alexander-Universität Erlangen-Nürnberg (Erlangen, Germany); University of Cologne (Cologne, Germany); Albert Einstein; sponge; absorption; absorb; water; tree; gravitation; gravity; molecule; diameter; hertz; Fengxian Fan, Eric Parteli, and Thorsten Pöschel; discrete element method; research; granular convection; convection of the granular material; rectangle; rectangular; sphere; spherical; millimeter; cylinder; cylindrical; calculation; trajectory; velocity; centimeter; pressure; multiplicative inverse; inversely; ratio; function; functionality; linearity; linear; industry; industrial.