Highly Flexible Conductors

February 13, 2017

Metals are excellent

conductors of electricity, and metal

wires are used as conductors for such varied applications as

high voltage transmission lines and the thin conductors in

integrated circuits.

Aluminum,

reinforced with steel, is an adequate conductor for power transmission, and aluminum was also the principal conductor in early integrated circuits. The

nanoscale conductors in today's high density integrated circuitry require a more conductive metal, so

copper is used. The transition from aluminum to copper was not that easy, since a complex

damascene process was required to form the

copper interconnects.

The dimensions of most

materials change with

temperature, one notable exception being the

alloy,

invar, the development of which secured the 1920

Nobel Prize in Physics for

Charles Édouard Guillaume. Copper and aluminum, for example, have very large

coefficients of thermal expansion, 17 and 23 ppm/°C, respectively.

Charles Édouard Guillaume (1861-1938)

One of his first publications estimated the temperature of space as 5.6 K; or, by his conversion, -267.4 °C.[1]

(Guillaume's official Nobel Prize portrait, via Wikimedia Commons, modified for artistic effect.)

The most common

printed circuit board material,

FR-4, has a

thermal expansion coefficient of about 13 ppm/°C, and

silicon has a thermal expansion coefficient of about 2.5 ppm/°C. Copper traces will shrink faster on these when the temperature is lowered, forcing the conductors to stretch. This is generally not a problem for integrated circuits and printed circuit boards, since these pure metals are highly

elastic; that is, they recover their shape after being stretched slightly.

However, the recoverable

elastic strain of metals and alloys is typically far less than a percent. What if we need an electrical conductor that will stretch or flex over a much larger range? There are special cases with exceptional elastic performance in metals. A 2011 study of the elastic strain limit of

single crystal nanowires of copper with a

diameter of about 6

nm showed a large recoverable strain as high as 7.2%.[2]

Elastic

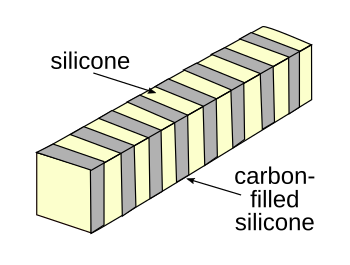

composite materials are available if the electrical conductivity need not be as good as that of a metal. My first experience with such materials was an

elastomeric connector for attaching

OLED displays to a

test fixture. The elastomeric connector in that case was Zebra™ strip, a

carbon filled

silicone interleaved with unfilled silicone to make an assembly that conducts in just one direction (see figure). A variant of this concept has a sea of parallel wires embedded in the

elastomer.

Schematic of a Zebra™ strip elastomeric connector.

It can be seen that there is electrical conductivity in just one direction.

(Modified Wikimedia Commons image by Roland Mattern.)

The discovered high elasticity of copper nanowires of ref. 2 shows that nanoscale structures are a likely path to the development of flexible and stretchable conductors for such applications as

wearable electronic devices. In a recent article in

Science,

chemists and

engineers at

Stanford University (Stanford, California),

Nanjing University (Nanjing, China), the

SLAC National Accelerator Laboratory (Menlo Park, CA),

Gyeongsang National University (Jinju, South Korea), the

Hong Kong University of Science and Technology (Kowloon, Hong Kong), and the

Samsung Advanced Institute of Technology Yeongtong-gu (Gyeonggi-do, South Korea), have reported on their creation of highly stretchable

polymers in which

semiconducting polymer nanofibrils are contained in a soft elastomer.

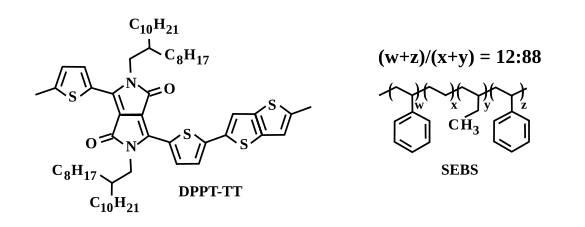

The

researchers have named this

conjugated-polymer/elastomer

phase-separated material CONPHINE.[4] The material has a conductive phase of a conjugated polymer of DPPT-TT composed of repeating unit alternating

single and

double bonds embedded in an elastomer matrix of SEBS (see figure).[3]

Monomer units of the polymers DPPT-TT and SEBS. (Drawn using Inkscape.)

The conductivity of the DPPT-TT arises from

delocalized π-electrons, and molecular nanofibrils a few tens of nanometers in length of this phase are confined to a spatial dimension less than 100 nm. The elongated geometry helps the

charge transport in a given direction.[3] Fabrication is uncomplicated, since it involves just mixing the two polymers. The components

self-assemble into the conductive structure.[3]

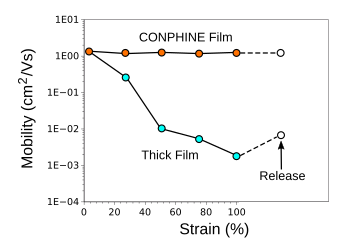

Because of the nanoconfinement, the

elastic modulus of the conjugated polymer is significantly reduced, and this delays the onset of

crack formation under

strain.[4] The CONPHINE material has a high charge carrier conductivity that approaches that of

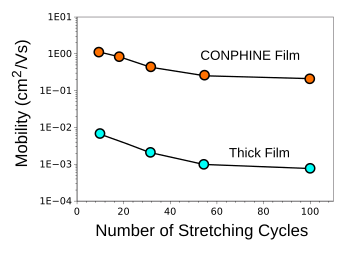

amorphous silicon, even when stretched to twice their original length, which is 100% strain (see figure).[3] The research team has fabricated stretchable

transistors and a

skin-like,

finger-wearable,

driver circuit for a

light-emitting diode.[4]

Mobility vs strain for CONPHINE and thick film polymers.

(Graphed using Gnumeric from data in ref. 4.[4]

Mobility vs stretching cycles for CONPHINE and thick film polymers.

(Graphed using Gnumeric from data in ref. 4.[4]

![]()

References:

- Charles-Edouard Guillaume, "La Température de L'Espace (The Temperature of Space)," La Nature, vol. 24, 1896 (From Los Alamos National Laboratory, via archive.org).

- Y. Yue, P. Liu, Z. Zhang, X. Han, and E. Ma, "Approaching the theoretical elastic strain limit in copper nanowires," Nano Lett., vol. 11, no. 8 (August 10, 2011), pp. 3151-5, doi: 10.1021/nl201233u.

- Simone Napolitano, "Perspective - Flexible Electronics, Staying conductive in the stretch," Science, vol. 355, no. 6320 (January 6, 2017), pp. 24-25, DOI: 10.1126/science.aal4113.

- Jie Xu, Sihong Wang1, Ging-Ji Nathan Wang, Chenxin Zhu, Shaochuan Luo, Lihua Jin, Xiaodan Gu, Shucheng Chen, Vivian R. Feig, John W. F. To, Simon Rondeau-Gagné, Joonsuk Park, Bob C. Schroeder, Chien Lu, Jin Young Oh, Yanming Wang, Yun-Hi Kim, He Yan, Robert Sinclair, Dongshan Zhou, Gi Xue, Boris Murmann, Christian Linder, Wei Cai, Jeffery B.-H. Tok, Jong Won Chung, and Zhenan Bao, "Highly stretchable polymer semiconductor films through the nanoconfinement effect," Science, vol. 355, no. 6320 (January 6, 2017), pp. 59-64, DOI: 10.1126/science.aah4496

Permanent Link to this article

Linked Keywords: Metal; electrical conductor; conductor of electricity; wire; overhead power line; high voltage transmission line; integrated circuit; aluminum; aluminium-conductor steel-reinforced cable; nanoscopic scale; nanoscale; copper; damascening; damascene; copper interconnect; material; temperature; alloy; invar; Nobel Prize in Physics; thermal expansion; coefficient of thermal expansion; Charles Édouard Guillaume (1861-1938); academic publishing; publication; outer space; kelvin; K; Celsius; °C; Nobel Prize; Wikimedia Commons; printed circuit board; FR-4; thermal expansion coefficient; silicon; elasticity; elastic; elastic strain; single crystal; nanowire; diameter; nanometer; nm; composite material; elastomeric connector; OLED display; test fixture; carbon; silicone rubber; electrical conductivity; wearable electronic device; Science; chemist; engineer; Stanford University (Stanford, California); Nanjing University (Nanjing, China); SLAC National Accelerator Laboratory (Menlo Park, CA); Gyeongsang National University (Jinju, South Korea); Hong Kong University of Science and Technology (Kowloon, Hong Kong); Samsung Advanced Institute of Technology Yeongtong-gu (Gyeonggi-do, South Korea); polymer; semiconductor; semiconducting; research; researcher; conjugated system; phase-separated; single bond; double bond; monomer; Inkscape; delocalized electron; pi bond; π-electron; charge carrier; charge transport; self-assembly; elastic modulus; fracture; crack formation; strain; amorphous silicon; transistor; skin; finger; driver circuit; light-emitting diode; electrical mobility; Gnumeric