Friction and Wear at the Atomic Level

February 6, 2013

Introductory

physics courses treat

friction in an idealized way

without postulating any mechanism. There's

static friction, which can be characterized as the

force that prevents objects sliding down a slope; and, there's also

dynamic friction, which is the friction between moving bodies. As we all know from sliding heavy boxes of

books, dynamic fiction is usually smaller than static friction; that is, it's hard to get something sliding, and it's easier to keep it moving.

Guillaume Amontons published the first theory of static friction in 1699. He proposed that it was merely the force required to raise an object above the height of surface irregularities. You can see how you would need to lift a ball completely out of a surface dimple before you can get it to roll. In 1750,

Leonhard Euler, who applied his hand to so many fields,

quantified static friction by the

angle of repose of an object on an

inclined plane.[1]

The angle of repose is the maximum angle for which the object will remain in place without sliding. This angle is the

arctangent of the

coefficient of static friction between the surfaces. It's interesting that the arctangent function,

ATN, was the only

inverse trigonometric function defined in the early

programming language,

BASIC. Euler was the first to identify the difference between static and dynamic friction.

A 1753 pastel portrait of Leonhard Euler by Jakob Emanuel Handmann (1718–1781).

This portrait resides at the Kunstmuseum Basel.

Whenever I read the word, "savant," I think of this portrait. The headpiece is a nice touch.

(Via Wikimedia Commons))

Amontons' mechanism for static friction is quite believable, but it fails in the case of extremely smooth surfaces. According to Amonton, perfectly smooth surfaces should have no static friction, but we have the modern example of

gauge blocks. Gauge blocks are finely dimensioned material blocks with faces

polished to an extreme smoothness. When the faces of gauge blocks are pressed against each other, they will bond together with considerable force.

This example, and many others, lead us to the idea that some friction arises from

atomic interactions between the sliding object and the surface. One major clue is that the coefficient of friction depends on both the material composition of the sliding object and that of the surface. These two materials make a friction "couple."

The following table lists the coefficient of static friction

μs for some common friction couples.[2] Note especially the case of

Teflon® (Polytetrafluoroethylene, PTFE) against itself or steel.

In complement to the

firefighter's slogan, "Where there's smoke, there's fire," there's the

tribologist's slogan, "Where there's dynamic friction, there's wear." It takes just a

pencil to remind us that rubbing materials against each other will deposit one material on the other. Our

analytical instruments have evolved to the point that we can now examine this process at the atomic level and examine atomic wear.

An example of atomic ware.

Figures from US design patent D153826 for an atomic coffee machine by Giordano Robbiati (May 17, 1949).

(Via Google Patents.)[3)]

Two

scientists from the

University of Pennsylvania School of Engineering and Applied Science,

Tevis D. B. Jacobs (

Materials Science and Engineering) and

Robert W. Carpick (

Mechanical Engineering and Applied Mechanics) have just published results of their studies of the atomic-scale wear of

silicon on

diamond.[4-5]

The motivation for such studies is the importance of wear on

nanoscale devices. Such devices are built from only small bits of material, so every atom counts. Although most applications require

mechanical devices to function for many cycles, wear can limit nanoscale devices to just a few hundred mechanical cycles.[5] Although it's possible to prevent the more extreme forms of wear, such as

fracture and

plastic deformation, which involve thousands or millions of atoms, such devices will still shed atoms a few at a time, a process called atomic attrition.[4-5]

For their studies, the Penn researchers placed an

atomic force microscope (AFM) module into a

transmission electron microscope (TEM). The AFM allowed the precise control of the sliding distance, sliding speed and contact load of its silicon probe tip, and the TEM enabled observation of the wear of the probe at 100,000

magnification.[5]

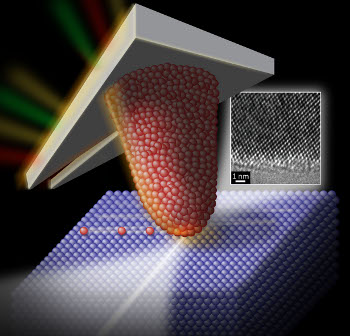

Artist's conception of a silicon atomic force microscope tip sliding over a diamond surface, leaving behind atoms of silicon.

The inset shows a transmission electron micrograph of the tip.

University of Pennsylvania image by Felice Macera.)

The

experiments involved sliding the AFM silicon tip against a harder diamond surface and the measurement of the

volume of atoms removed in each slide.5] Volumes as small as 25 ± 5

nm3 could be measured.[4] Says study co-author, Tevis Jacobs,

"We can watch the whole process live to see what happens while the surfaces are in contact... Then, after each pass, we use the TEM like a camera and take an even higher magnification picture of the tip. We can trace its outline and see how much volume has been lost, down to as small as 25 cubic nanometers, or about 1250 atoms... We are measuring changes in volume that are one thousand times smaller than can be seen using other techniques for wear detection."[5]

Although the TEM can't detect atomic attrition directly, since individual atoms are too small to see, the results of the experiments rule out fracture and plastic deformation of the silicon probe, and they are consistent with atomic attrition.[5] In this case, the problem of wear at the nanoscale is reduced to understanding

chemical kinetics and

reaction rates between the friction couples.[5] The research was supported by the

National Science Foundation's Nanomanufacturing Program.[5]

References:

- Leonhard Euler, "Sur le Frottement des Corps Solides," Mémoires de l'académie des sciences de Berlin, 1750, pp. 122-132.

- Coefficients of Static Friction Table, Wikipedia.

- Giordano Robbiati, "Design for a Coffee Maker or Similar Article," US Design Patent No. D153826 (May 17, 1949).

- Tevis D. B. Jacobs and Robert W. Carpick, "Nanoscale wear as a stress-assisted chemical reaction," Nature Nanotechnology (January 27, 2013), doi:10.1038/nnano.2012.255

- Penn Research Shows Mechanism Behind Wear at the Atomic Scale, University of Pennsylvania Press Release, January 29, 2013.

Permanent Link to this article

Linked Keywords: Physics; friction; hypothesis non fingo; without postulating any mechanism; static friction; force; kinetic friction; dynamic friction; book; Guillaume Amontons; Leonhard Euler; quantification; >quantify; angle; inclined plane; arctangent; coefficient of static friction; inverse trigonometric function; programming language; BASIC; pastel; portrait painting; portrait; Leonhard Euler; Jakob Emanuel Handmann (1718–1781); Kunstmuseum Basel; Wikimedia Commons; gauge block; polishing; polished; atom; atomic; polytetrafluoroethylene; Teflon®; cast iron; copper; concrete; rubber; glass; steel; copper; aluminum; brass; polyethylene; PTFE; firefighter; slogan; tribology; tribologist; pencil; scientific instrument; analytical instrument; design patent; atomic coffee machine; Google Patents; scientist; University of Pennsylvania; School of Engineering and Applied Science; Tevis D. B. Jacobs; Materials Science and Engineering; Robert W. Carpick; Mechanical Engineering and Applied Mechanics; silicon; diamond; nanotechnology; nanoscale device; machine; mechanical device; fracture mechanics; fracture; plastic deformation; atomic force microscope; transmission electron microscope; magnification; silicon; diamond; transmission electron micrograph; Felice Macera; experiment; volume; nanometer; nm; chemical kinetics; reaction rate; National Science Foundation; Nanomanufacturing Program; US Design Patent No. D153826 (May 17, 1949).