Bottle Flow

June 15, 2020 As they say, "A place for everything, and everything in its place," which is a proverb attributed to Benjamin Franklin (1706-1790). In households, this place is usually a jar or bottle for containing a liquid. Some liquids are watery, so they flow easily out of their container. However, others like ketchup are thick, so they present a fluid flow problem. While my preferred ketchup bottle is the newer, plastic squeeze bottle that performs ketchup extraction perfectly, ketchup was only available in glass bottles until recently. The common technique for getting ketchup to flow from a glass bottle is to hit the bottle with the palm of your hand. Ketchup is a non-Newtonian fluid, and such fluids will change viscosity with application of external forces. Other examples of non-Newtonian flow are the blood coursing through your arteries and veins, and inkjet printing. Rheology, from the Greek words, ρεω (rheo, flow) and λογια (logia, the study of), is a branch of mechanics for the study of flow. The motto of The Society of Rheology is πάντα ῥεῖ (panta rei, Everything Flows). This expression is associated with the 5th century BC, the Greek philosopher, Heraclitus of Ephesus, who also observed that you can't step in the same river twice, since it would have changed in between steps. Heraclitus considered fire to be the most fundamental element and progenitor of all the other elements.

Logo of The Society of Rheology.

The Society of Rheology was officially formed on December 19, 1929, and it was one of the five founding members of the American Institute of Physics.

The Society of Rheology has fewer than 2,000 members, and it publishes the Journal of Rheology.

(Society of Rheology image.)

The Roman philosopher, Lucretius (c. 99 BC - c. 55 BC), wrote about rheology in his book, De Rerum Natura (On the Nature of Things), Book II, ll. 391-397.[2-3]

"We see how quickly through a colander the wines will flow; how, on the other hand, the sluggish olive oil delays: no doubt, because 'tis wrought of elements more large, or else more crook'd and intertangled. Thus it comes that the primordials cannot be so suddenly sundered one from other, and seep, one through each several hole of anything."[3]Lucretius proposes using a colander as a rheometer. Many of today's laboratory rheometers function by the same principle by measuring the time it takes for fluid to flow through a pipe or capillary. Other rheometers examine the force transmitted through the fluid from a moving surface to another surface. Isaac Newton (1642-1727), proposed a theory of viscosity, the resistance to flow, in his Principia, where he writes, [4-5]

"The resistance which arises from the lack of slipperiness of the parts of the liquid, other things being equal, is proportional to the velocity with which the parts of the liquid are separated from one another."Viscosity is the scientific term for Newton's "lack of slipperiness." Small flow channels have a different viscosity law. Physicists at the Georgia Institute of Technology used atomic force microscopy (AFM) to find that confinement of a low viscosity fluid in a nanometer-scale channel causes the fluid to become more viscous.[6] Their experiments showed that the viscoelastic relaxation times for water and silicone oil confined in such nanometer-sized channels are orders of magnitude longer than the usual values.[6] The relaxation times for water were as slow as a tenth of a second at room temperature, which is comparable to that for supercooled water at 170-210 kelvin.[6] The ketchup effect was still present, since shaking reduced this scale-induced viscosity.[6] While viscosity of the liquid is a huge factor affecting the emptying of a bottle, another factor is the necessity of air getting back through the opening, forming a bubble that replaces the missing liquid. Bubbles are fascinating to children, and they also fascinated Leonardo da Vinci (1452-1519), who wrote about the motion of air bubbles in water in the Codex Leicester, the main topic of which is fluid dynamics.[8] The bubble dynamics of bottle emptying was recently investigated by two mechanical engineers at the Indian Institute of Technology (Roorkee, India) and published in a recent issue of the journal, Physics of Fluids.[7-8] They used high-speed photography to examine the bubble dynamics for a commercial bottle containing water, glycerol, and silicone oil.[8] Their research of the rate at which bottles empty has applications beyond the food industry.[8] TABLE. Properties of the studied fluids at 30 °C.

| Fluid | Density (kg/m3) |

Viscosity (Pa-s) |

Surface Tension (N/m) |

Inverse Viscosity no., Nf |

| Water | 1000 | 0.00105 | 0.072 | 8077.34 |

| Glycerol | 1260 | 0.80 | 0.063 | 11.322 |

| Silicone oil | 970 | 0.98 | 0.017 | 7.114 |

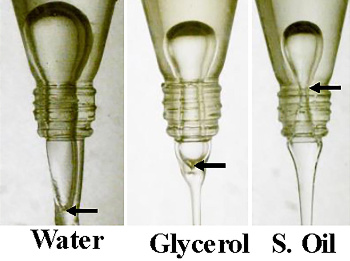

Says study author, Lokesh Rohilla, "Bubble dynamics inside the bottle are too complex to study, so we divided the bubble interfacial growth into different stages to comprehend them."[8] A phenomenon that everyone has experienced is that bottles will empty faster when they're angled from the horizontal. This increases what's called the bubble pinch off frequency, and this angle depends on the fluid properties.[8] If the bottle opening is too small, surface tension forces prevent the fluid from exiting. If the bottle opening is larger, a spherical bubble train with a rhythmic pinch-off frequency forms. Bottle opening of larger size allows creation of a channel of air entering the liquid. When the diameter increases to the point at which the bottle is a cylinder, the liquid moves out as a rigid body.[7]

Formation of encapsulated bubbles in water, glycerol, and silicone oil, showing where bubble pinch-off occurs.

Says study author, Lokesh Rohilla, "We've also observed an encapsulated bubble while discharging fluid in a vertically upended bottle... Encapsulated bubbles have pinch off sites outside the bottle mouth, contrary to intuition."[8]

(American Institute of Physics image by Lokesh Rohilla.)

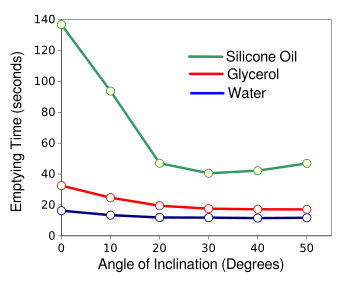

Everyone wants their ketchup faster, and the researchers founds that the bottle emptying time was reduced by decreasing the volume of each pinched-off bubble and increasing pinch-off frequency for low viscosity liquids, such as water; or, by increasing the volume of each pinched-off bubble at a comparatively lower frequency for high viscosity liquids such as glycerol and silicon oil.[7] No matter the liquid, an asymptotic emptying point was found at a change in mode from slugging to a stratified pattern.[7] This happened in all liquids at about 20 degrees inclination for the particular bottle used (see figure).[7]

The effect of the angle of inclination on emptying time for the three different fluids.

In each case, the asymptote appears at about 20 degrees of inclination for the particular bottle used in the experiments.

(Created using Gnumeric from data in Table II of ref. 7.[7])

The principal finding of the study is the asymptote that occurs at a particular angle, irrespective of the fluid properties.[7] Says Rohilla,

"Our experiments suggest there is a critical angle of inclination, after which any further increase in the inclination of the bottle won't lead to further reduction in the bottle emptying time... This occurs due to the saturation of the voidage, space occupied by air within liquid surrounding, at the bottle's mouth with the angle of inclination."[8]As corresponding author, Arup Kumar Das, states, "We can manipulate the bottle discharge pattern by manipulating bottle geometry... An intuitive product-specific bottle design will enable better control of its discharge rate."[8]

References:

- About The Society of Rheology, The Society of Rheology Website.

- TITI LVCRETI CARI DE RERVM NATVRA LIBER SECVNDVS, Book II, ll. 391-397, Latin Text, via The Latin Library.com.

"Et quamvis subito per colum vina videmus

perfluere, at contra tardum cunctatur olivom,

aut quia ni mirum maioribus est elementis

aut magis hamatis inter se perque plicatis,

atque ideo fit uti non tam diducta repente

inter se possint primordia singula quaeque

singula per cuiusque foramina permanare."

- Lucretius, "On the Nature of Things," Translated by William Ellery Leonard, Book II, ll. 391-397, via Classics.MIT.edu.

- Roger I. Tanner and Kenneth Walters, "Rheology: an historical perspective," Elsevier, 1998, 255 pages.

- I.S. Newton, "Philosophiae Naturalis Principia Mathematica," 1st Ed., 1687, Bk 2, Sect. IX, via Project Gutenberg. In Latin,

"Resistentiam, quae oritur ex defectu lubricitatis partium Fluidi, caeteris paribus, proportionalem esse velocitati, qua partes Fluidi separantur ab invicem."

- Tai-De Li and Elisa Riedo, "Nonlinear Viscoelastic Dynamics of Nanoconfined Wetting Liquids," Phys. Rev. Lett. vol. 100, no. 10 (March 14, 2008), p. 106102, DOI:https://doi.org/10.1103/PhysRevLett.100.106102.

- Lokesh Rohilla and Arup Kumar Das, "Fluidics in an emptying bottle during breaking and making of interacting interfaces," Physics of Fluids, vol. 32, no. 4 (April 7, 2020), Article no. 042102, https://doi.org/10.1063/5.0002249. A PDF file of this paper is presently available here.

- Bubble dynamics reveal how to empty bottles faster, American Institute of Physics Press Release, April 7, 2020.