Carbon Nanotube Textile

May 25, 2017

One

childhood memory I have is the visage of a strange little

bridge on the

road between our house and the

downtown area. The bridge crossed the

Mohawk River, a span of just 250 feet. What was strange about that bridge was the pair of short

girder arches on the sides of the otherwise contiguous road surface. This bridge didn't really look like a bridge, and I always thought that the girders were

decorative, or a way to separate the roadway from the

sidewalk. That was before I learned about

truss bridges.

Rather thick

beams would have been required to carry the

weight of a roadway over such a gap. Lesser

materials served the same purpose by changing the

one-dimensional beams into a

two-dimensional structure. Common

I-beams were

riveted together to create a type of truss bridge called a "pony truss" bridge, an inexpensive structure suited for such a short span. It's no surprise that the dominant

geometrical element of a

truss is the

triangle.

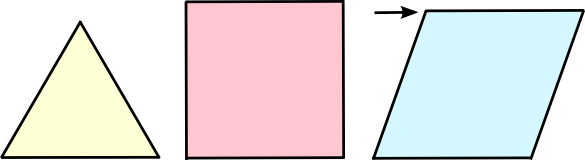

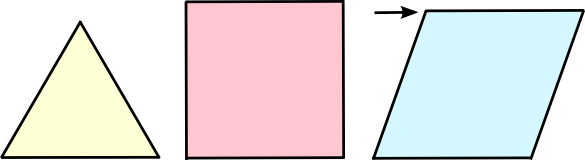

As I explained in a

previous article (Non-Brittle Ceramic Structures, November 21, 2014), while a

quadrilateral assembled from equal length pieces can have a variety of

angles, the angles of a triangle are fixed by their lengths. This property leads to the

dimensional stability of structures built from triangles (see figure).

|

| Three equal sides will assemble into only one triangle, but four equal sides can assemble into quadrilaterals of various angles, such as a square (center) and a rhombus (right). The transition from a square to a rhombus is often used as an example of shear. (Created using Inkscape.) |

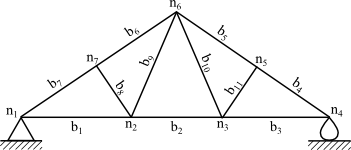

While pony truss bridges are rare, an example of a truss with a long history is probably near where you're seated. In 1839,

Camille Polonceau, a

French railway engineer,

invented the eponymous Polonceau truss, as shown in the figure. This truss is a common element of

roof construction. In honor of his invention, Polonceau's name was among the

72 names engraved on the Eiffel Tower, joining such scientific luminaries as

Cauchy,

Coriolis,

Coulomb,

Gay-Lussac,

Fourier,

Lagrange,

Laplace, and

Lavoisier.

The idea that linear structural elements can be assembled into

strong two-dimensional structures is especially important in the

nanoscale realm.

Multi-walled carbon nanotubes have shown themselves to be individually strong, with

tensile strength about two

orders of magnitude greater than that of

stainless steel.[1] Among other benefits, carbon nanotubes are lighter than

aluminum, and more

conductive than

copper. The utility of these exceptional properties can only be realized in practice when these carbon nanotubes can be joined together to form larger structures.

The problem, of course, is how do you "glue" nanotubes together? A

research team from the

Department of Mechanical Science and Engineering at the

University of Illinois Urbana-Champaign has produced a tough conductive

textile by "capillary splicing" of carbon nanotubes.[2-3] While the term, "capillary splicing," is used for the technique in which things such as

fiberoptic cables are joined through insertion into the separate ends of a

capillary tube, the Illinois technique uses

capillary action in a more general sense. Surfaces will attract each other in order to reduce their

surface energy, the difference in energy between surface

atoms and atoms in the bulk of a

material.

Einstein's first

publication was on capillary action.[4]

As

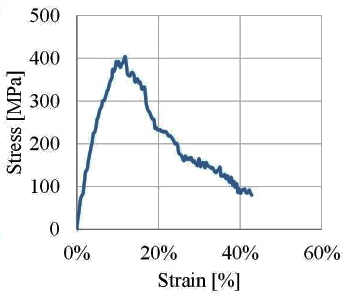

mobile devices become smaller, there's a push to make them

flexible, as well, but flexure of

electrical conductors is only possible when they resist

fracture. The Illinois team was able to achieve high strength in a nanotube fabric by alignment of the nanotubes on a

substrate, where they couple together through strong

van der Waals forces.[2] the average strength of the as-prepared nanotube fabric was 170

MPa, and its average fracture energy was 16

kJ/

m2, values that are fifty times higher than those for

metal nanofilms.[2]

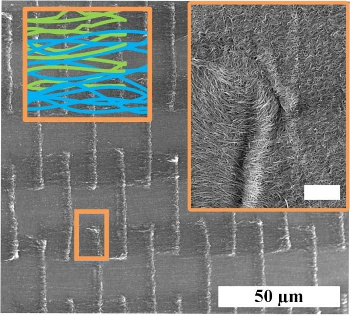

To produce their textile of carbon nanotubes, they first deposited a

catalyst on a

Silica glass substrate. The catalyst was deposited as a staggered pattern not unlike that seen in

brickwork, and in tough

natural materials such as

nacre and

bamboo.[3] Then, vertically-aligned carbon nanotubes were

synthesized by

chemical vapor deposition to produce

parallel lines of 5 μm width, 10 μm length, and 20-60 μm height.[3] This nanotube array was then

coated with

polyvinyl alcohol and

polymethyl methacrylate (PMMA).[3] When the substrate was floated onto

water, the PMMA carrier film was released.[2]

acetone was used to dissolve the PMMA after this film was mounted for

tensile testings to produce a bare nanotube textile.[2]

Says

Sameh Tawfick, an

assistant professor of mechanical science and engineering at Illinois,

"To our knowledge, this is the first study to apply the principles of fracture mechanics to design and study the toughness of nano-architectured CNT textiles. The theoretical framework of fracture mechanics is shown to be very robust for a variety of linear and non-linear materials... Flexible electronics are subject to repeated bending and stretching, which could cause their mechanical failure. This new CNT textile, with simple flexible encapsulation in an elastomer matrix, can be used in smart textiles, smart skins, and a variety of flexible electronics."[3]

Partial

funding for this research came from the

Office of Naval Research.[2]

References:

- Mechanical properties of carbon nanotubes Web Page on Wikipedia.

- Yue Liang, David Sias, Ping Ju Chen, and Sameh Tawfick, "Tough Nano‐Architectured Conductive Textile Made by Capillary Splicing of Carbon Nanotubes," Advanced Engineering Materials, Early View Article (March, 2017), DOI: 10.1002/adem.201600845.

- Rick Kubetz, "Wonder material? Novel nanotube structure strengthens thin films for flexible electronics," University of Illinois Urbana-Champaign Press Release, April 21, 2017.

- Albert Einstein, "Folgerungen aus den Capillaritätserscheinungen," Annalen der Physik, vol. 309, no. 3 (1901), pp. 513-523, doi:10.1002/andp.19013090306. A page image file can be found here.