Cold Work on the Nanoscale

January 2, 2017

My first

metallurgy lesson came early in life as I was bending

aluminum to make

chassis for

electronic circuitry. I started building electronic circuits in

elementary school using components harvested from old

television receivers. The receivers of that period, and my circuits, were built from

vacuum tubes. I could build an

audio amplifier from just four or five vacuum tubes.

Soldering wires was the easy part. The hard part was

machining holes in an

aluminum chassis to mount the tube

sockets,

transformers, and

controls.

Transformers typically required a large

square hole, and my only

tool for making these was an

electric drill. I would

drill a chain of small holes near the

perimeter of the square, and cut a path through the line of holes using a small

file, a tedious task. Eventually, I discovered that I only needed to cut three sides of the square. Repeatedly

bending the aluminum back and forth would easily

break off the final side. I had discovered

work hardening.

As everyone familiar with

cooking foil and

beverage cans knows, aluminum is a

soft metal. It's easily created in its pure

elemental form by

electrolytic reduction of

aluminum oxide dissolved in a

molten solution by a

modified Hall process.[1] Pure metals, as

cast and distinguished from

alloys, are soft. The repeated bending (cold-working) forms

dislocations in the

crystal lattice that change the aluminum from a

ductile to a

hard and

brittle material.

Forging and

shot peening are two of the more useful applications of work hardening. In forging, a component of near-net shape is

hammered into a

die to bring it to its desired shape. The forging process hardens the material by cold working, but forging is often done

at higher temperature to keep the material

ductile. A

video of cold forging of aluminum can be found in ref. 2.[2]

Peening is the process of hammering the

surface of a metal to increase the surface hardness. The process of hammer peening was used by

blacksmiths for

centuries without an understanding of why it works. Some readers may have seen a

ball peen hammer, but wondered about its purpose (see photograph).

Shot peening is a more rapid process that pelts a surface with a stream of hard

beads to provide the work hardening.

Surprisingly, shot peening was only invented about a

century ago, probably because there wasn't enough demand for a rapid peening process before

mass production of such items as

automobiles. Shot peening not only hardens the surface, but it puts the surface in

compression, and this

compressive force prevents surface

cracks from growing, so it will increase

fatigue life. Shot peening is mostly used in the production of

gears,

crankshafts and their associated

cams, and

turbine blades.

The

shot used is peening is chosen to be much harder than the peened material, but what about the

complementary system of soft shot against a hard target? That's the approach taken by

materials scientists and

mechanical engineers at

Rice University (Houston, Texas) and the

University of Massachusetts, Amherst, as a way to modify the

mechanical properties of

silver nanoparticles.[3-5] The results of their

research have been published as a recent article in

Science.[3] The research was led by Rice materials scientist,

Edwin Thomas, and the lead

author of the

paper is

Ramathasan Thevamaran, a Rice

postdoc.[4]

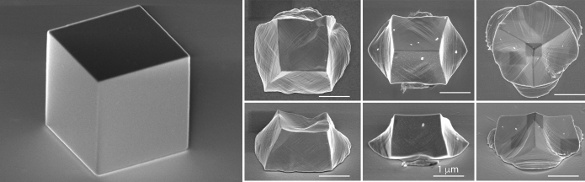

The silver particles used for these

experiments needed to be as perfect as possible, so they were

synthesized as

single crystals by

bottom seeded crystal growth.[4] The resulting

nanoscale cubes were about 1.4

micrometers on a side, and they were shot at a hard

silica target at about 400

meters per second using a

laser technique.[3] This laser-induced projectile impact test (LIPIT) was developed at Rice University in 2012 for experiments on

polymer and

graphene film materials.[5-6]

The LIPIT system works by rapid laser heating of a thin

gold film beneath a polymer film on which the cubes are placed. The laser

power vaporizes the gold film, and the resulting expansion of the polymer film launches the nanocubes.[4] The laser apparatus was designed to accurately deposit the cubes at a desired

orientation so the affect of impacts at every

angle could be determined.[4] The silver cubes hit the silica surface at

supersonic velocity, transforming their

momentum into a huge

deformation energy over a half

millimeter travel distance.

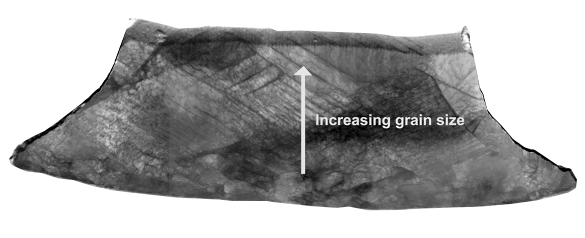

The cubes were initially at

room temperature, but impact increased the temperature by about 350 degrees

Fahrenheit, a temperature which allowed dynamic

recrystallization of the silver.[4] Says Thomas,

"The high-velocity impact generates very high pressure that far exceeds the material's strength... This leads to high plasticity at the impact side of the cube while the top region retains its initial structure, ultimately creating a grain-size gradient along its height."[4]

The resulting high

strain rates, strain gradients, and recrystallization from these impacts created a gradient nano-grained structure from the nearly defect-free single-crystal nanocubes.[3-4] The gradient was at least an

order of magnitude greater than what has been produced by other techniques.[4]

Electron microscope analysis of the cubes eight days after impact showed that the gradient structure was still extant.[4]

Strain gradients such as those produced can create ductile and

tough metals.[3] Such a processing technique might give materials with high strength that are less susceptible to

brittle fracture.[4] The technique might be used to enhance

cold spray processing.[4]

References:

- Charles M. Hall, "Process of reducing aluminium from its fluoride salts by electrolysis," US Patent No. 400,664, April 2, 1889.

- Aluminium Forging, YouTube Video, June 29, 2011.

- Ramathasan Thevamaran, Olawale Lawal, Sadegh Yazdi, Seog-Jin Jeon, Jae-Hwang Lee, and Edwin L. Thomas, "Dynamic creation and evolution of gradient nanostructure in single-crystal metallic microcubes,"Science, vol. 354, no. 6310 (Oct 21, 2016), pp. 312-316, DOI: 10.1126/science.aag1768

- Mike Williams, "Smashing metallic cubes toughens them up," Rice University Press Release, October 20, 2016.

- Jae-Hwang Lee, David Veysset, Jonathan P. Singer, Markus Retsch, Gagan Saini, Thomas Pezeril, Keith A. Nelson, and Edwin L. Thomas, "High strain rate deformation of layered nanocomposites," Nature Communications vol. 3 (November 6, 2012), Article no. 1164, doi:10.1038/ncomms2166.

- Mike Williams, "Microbullets reveal material strengths, Rice University Press Release, October 30, 2012.

- Smashing silver micro-cubes toughens them up, Rice University YouTube Video, October 20, 2016.