3D-printing Stainless Steel

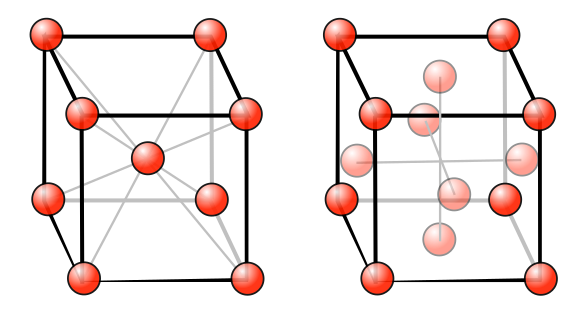

December 11, 2017 The door of our current refrigerator is stainless steel. It's good that our children are grown, since everyone knows that an important function of a refrigerator door is to hold children's drawings. This is usually accomplished with refrigerator magnets, and the stainless steel door of our refrigerator is non-magnetic, so magnets don't stick. While stainless steels, like other steels, have a high concentration of iron, the particular stainless steel used for our refrigerator must be an austenitic stainless steel, which means that the atoms are arranged in a face-centered cubic (FCC) crystal. There's another type of stainless steel, ferritic stainless steel, in which the atoms are arranged as a body-centered cubic (BCC) crystal. Ferritic stainless steel has the same BCC crystal structure as iron, and it is also magnetic.

body-centered cubic (BCC) and face-centered cubic (FCC) crystal structures.

(Created using Inkscape. Click for larger image.)

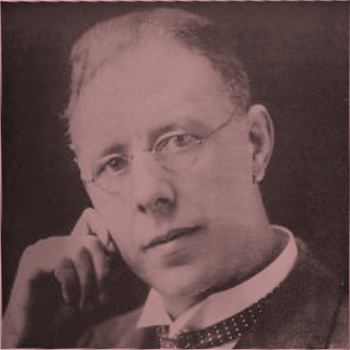

Refrigerator stainless steel is generally ANSI type 304, also known as "18-8" since its chemical composition is 18 percent chromium and 8 percent nickel with the balance as iron, plus a pinch of manganese, carbon and nitrogen. The 400 series contain no nickel, and those alloys are magnetic. One contributing factor to 304 stainless steel having the FCC crystal structure is that nickel is FCC in its elemental form. Why is the FCC form of stainless steel non-magnetic, while its BCC form is? The first reason relates to the number of electrons needed to bond the atoms together in the crystal. Electrons involved in the bonding cannot contribute to magnetism. Magnetism in transition metals arises from their d-electrons. It takes about two more electrons to bond an FCC crystal together than a BCC crystal, so we lose two of the d-shell magnetic electrons. Magnetic atoms also communicate their magnetic state to each other via an interaction known as the exchange field. The exchange field is responsible for the alignment of electron spins that results in magnetism. This exchange interaction depends on the distance between atoms, and this distance is different in the BCC and FCC forms of stainless steel. Stainless steel was discovered quite accidentally by English metallurgist, Harry Brearley (1871-1948). Brearley was doing routine testing of different alloys to find ones with high erosion resistance. He noticed that his pile of rejected samples had all rusted, except for one containing chromium.

Photo of English metallurgist, Harry Brearley (1871-1948), from a monument at the former Brown Firth Research Laboratories, Sheffield, England.

Brearley discovered stainless steel, supposedly by accident.

(Wikimedia Commons image by David Morris, modified for artistic effect.)

Most physics and analytical chemistry laboratories contain numerous vacuum systems fabricated from type 316 stainless steel. Stainless steel is a common material in surgical instruments, dental instruments, and other medical equipment, since it can be sterilized in an autoclave. Stainless steel is a common material in kitchen appliances, since it is rugged, durable, heat resistant, and it can be cleaned easily. Cutlery is generally made from stainless steel for these same reasons. Because of its low thermal conductivity, stainless steel cookware needs to be fabricated as a thin cladding over a thick core of aluminum or copper. As one who has machined stainless steel pieces, I can verify that stainless steel is a hard material with which to work. The Rockwell hardness (B-scale) of type 304 is slightly less than 90, while type 318 is slightly more. Compare this with the value for mild steel, about 70, brass, about 55, and aluminum, about 60. In any case, it makes more sense to eschew machining and fabricate complex components additively by a powder metallurgy method such as metal injection molding. Unfortunately, powder metallurgy has a sintering step that caused shrinkage of a powder compact. Machining is still required to achieve close tolerance, the density of a component is a few percent less than that of a cast part, and the mechanical properties of the material are not as good as those of a cast part. A team of materials scientists and mechanical engineers from Lawrence Livermore National Laboratory (Livermore, California), the Georgia Institute of Technology (Atlanta, Georgia), Ames Laboratory (Ames, Iowa), and Oregon State University (Corvallis, Oregon) has developed a laser powder-bed-fusion technique for additive manufacturing of type 316L stainless steel.[1-3] This process can produce mechanically tough components for conditions in marine, aerospace, automotive, and other harsh environments. The targeted material for this process was 316L "Marine grade" stainless steel, which resists corrosion and is highly ductile. This alloy is used in such applications as oil pipelines, welding, kitchen utensils, chemical equipment, medical implants, engine parts and radioactive waste storage.[2] Conventional techniques for strengthening this alloy typically reduce its ductility.[2] To make the 3D-printed steel perform as well as cast material, it was necessary to reduce porosity in the laser-fused metal powders.[2] The research team addressed the porosity problem through a density optimization process involving manipulation of the materials microstructure guided by computer simulation and confirmatory experiments.[2] Thin plates of 316L stainless steel were prepared for mechanical testing by placing a powder layer of metal alloy particles on a flat platform, raster-scanning the surface with a high-powered laser beam, lowering the platform, and repeating the steps. A sufficient number of steps produces complex shapes, such as rocket engines (see figure).[3]

Rocket engine fabricated with a powder-bed-fusion additive manufacturing process.

This engine, a prototype for the NX-01 Nanosat Launch Vehicle, took eight days to create at a cost of $10,000. This is at least an order of magnitude less that conventional fabrication.

(LLNL image.)

The computer-controlled process allows a tight control the microstructure of the material for a beneficial effect. Tests showed that the 3D printed stainless steels could attain up to three times the strength of steels made by conventional techniques and still have ductility.[3] Says Morris Wang, a LLNL materials scientist and lead author of this research,

"In order to make all the components you're trying to print useful, you need to have this material property at least the same as those made by traditional metallurgy... We were able to 3D print real components in the lab with 316L stainless steel, and the material's performance was actually better than those made with the traditional approach. That's really a big jump. It makes additive manufacturing very attractive and fills a major gap."[2]

Morris Wang (left) and Thomas Voisin of LLNL.

Wang and Voisin were members of the research team that developed 3D printing of the marine-grade 316L stainless steel.

(LLNL image.)

As LLNL scientist, Alex Hamza, describes it, the 3D-printed 316L has an interesting grain structure, with relatively large grains that contain cellular structures and other defects. There was a hierarchically heterogeneous microstructure, with length scales spanning nearly six orders of magnitude.[1] Says Hamza, "We didn't set out to make something better than traditional manufacturing; it just worked out that way."[2] The yield strength and tensile ductility surpass those of conventional 316L steels.[1] Since the LLNL process used a commercially available 3D printer and laser, it will be easy for others in industries such as aerospace, automotive, and oil and gas to create their own components.[2-3] The technique might be applied to create components from other alloys that are brittle and prone to cracking.[2]

References:

- Y. Morris Wang, Thomas Voisin, Joseph T. McKeown, Jianchao Ye, Nicholas P. Calta, Zan Li, Zhi Zeng, Yin Zhang, Wen Chen, Tien Tran Roehling, Ryan T. Ott, Melissa K. Santala, Philip J. Depond, Manyalibo J. Matthews, Alex V. Hamza, and Ting Zhu, "Additively manufactured hierarchical stainless steels with high strength and ductility," Nature Materials, Article No. 5021 (October 30, 2017), doi:10.1038/nmat5021.

- Jeremy Thomas, "Lab researchers achieve breakthrough in 3D printed marine grade stainless steel, LLNL Press Release, October 30, 2017.

- Robert F. Service, "3D printing doubles the strength of stainless steel," Science, October 30, 2017.

- 3D printing metal parts and novel materials, LLNL Web Site.

- Metal Additive Manufacturing, LLNL Web Site.

- Additive Manufacturing: The dawn of a new industrial revolution, YouTube video by Lawrence Livermore National Laboratory, September 5, 2013.