It's the Humidity

August 22, 2016

Everyone has heard the

saying, "

It's not the heat, it's the humidity." Most

mornings at my

home in

Northern New Jersey, I'm reminded that there's a lot of

water in the

air. On cool

summer mornings, my

automobile is covered with a thick layer of water,

condensed as

dew from the

atmosphere. On some

winter mornings, the dew appears as a thick layer of

ice. In an

earlier article (Fog Water Harvesting, December 2, 2010), I did a "

spherical cow calculation" of how effective my automobile is at collecting dew.

From

observation, I estimated that a heavy dew covered my car with about a

liter of water.

Approximating the

geometry of the car as two

rectangular parallelepipeds, one atop the other, having about 220 square feet exposed to the air (about 20

square meters) when the

undercarriage is ignored. This results in a collection

efficiency of about 50

milliliters per square meter.

The world is trending towards a

water crisis because of

pollution of

potable water, and the competing

human and

industrial needs for water. Humans need about forty liters of water per day.

Trees are natural

fog water harvesters, as demonstrated by the trees planted by

Charles Darwin on Ascension Island, a dry volcanic island. After two decades, the

leaves of these trees were harvesting enough water to grow

crops to feed hundreds of

British troops.

Trees with

needle-like leaves are the best harvesters, especially the ones that have leaves oriented

vertically, rather than

horizontally. The

California Redwood (Sequoia sempervirens) is so adept at harvesting water from the air that wet microclimates are created at its base.[1]

Fog water harvesting has been demonstrated using large

plastic nets, 32 square meters in

area, in

Lima, Peru.[1] During the cooler months of May through

November, such nets have captured as much as 590 liters in a single day. A more elaborate, double-net system produced an

average of 300 liters per day throughout the year, with 2650 liters being produced in a single day.[1] While automobile

metal and

glass act as fog water harvesters, such plastic netting is more effective, since air can

flow though it.

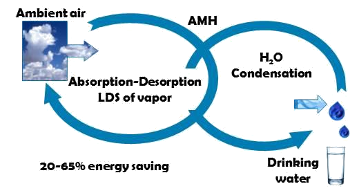

Scientists at

Technion-Israel Institute of Technology (Haifa, Israel) have gone beyond such passive fog water harvesting methods by developing an active type of atmospheric moisture harvester. While such active systems require

energy, the Technion system separates the

water vapor from the air before cooling and condensation as an energy-saving method.[2-3]

The simplest active fog harvesting system would use

electrical refrigeration to condense water vapor through cooling, an energy-intensive process. The Technion system uses a

liquid desiccant that separates the water vapor from air, so that just the water vapor needs to be cooled. Using

computer modeling, they found a 5-65% percent energy savings using their technique, depending on

climate conditions and the use of supplemental

solar energy.[2]

In a

recent article (Humidity Sensing, June 13, 2016), I reviewed

humidity-sensing technologies, some of which are based on changes in the the

mechanical properties of some

materials upon exposure to humidity. For example,

fibers such as

horsehair and

human hair will change

length or

twist when

braided as they

absorb water from the air.

Another example of a mechanical humidity sensor has an action similar to that of a

bimetallic thermometer. In such thermometers, the differential

thermal expansion of two bonded metal strips causes the

bimetallic strip to bend. A

salt-impregnated paper glued to a coil of

metal or another

elastic material that doesn't absorb water will similarly bend with changes in humidity.

Bimetallic strips can do a little

work in response to a temperature change, and the same is true for bimaterial humidity sensing strips.

low power wireless sensors that

harvest energy from a variety of

environmental sources, such as

light,

atmospheric pressure change, and

vibration, can harvest environmental energy, also, from humidity change. In most environments, the

diurnal variation in humidity is large.

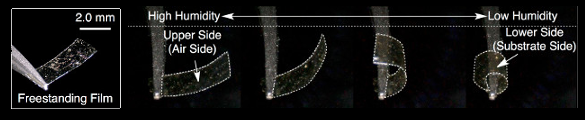

Scientists and

engineers at the

RIKEN Center for Emergent Matter Science (CEMS, Hirosawa and Sayo-cho, Japan), and the

University of Tokyo (Tokyo, Japan) have used the water vapor absorptive property of an

anisotropic polymer to form an

actuator that responds to even small changes in humidity.[4-6] The polymer, produced as a

thin film of

carbon nitride by

physical vapor deposition from

guanidinium carbonate, is lightweight, but

durable.[4] The film straightens and curls upon exposure to very small changes in ambient humidity; and, exposure to

ultraviolet light affects its water absorption ability.[5]

As happens often in science, the humidity sensitivity of the material was unexpected, and it was discovered by

accident. Says

Daigo Miyajima of CEMS,

"Our study began from a serendipitous finding. When we placed a compound called guanidinium carbonate into a high-temperature oven, we found that it formed not only a powdery substance - as is usual in similar processes—but also a yellowish film that stuck to the surface of the substrate. The film was a carbon nitrite polymer composed of stacked polymers of heptazine oriented parallel to the surface of the substrate."[5]

When the

research team started to

analyze this unusual film, first removing it from its substrate using warm water, they noticed its tendency to bend and straighten, seemingly at

random intervals.[5] They found that this behavior arose from extremely small changes in the ambient humidity.[5] Moving a

drop of water into the vicinity of the film would cause it to straighten. A

weight difference was detected between the straight and curled states, the weight of the curled state being just 68

nanograms per

square millimeter greater than the curled state.[5] This film was seen to respond to quantities of water as small as a few hundred nanograms per 10 square millimeters.[4]

It's proposed that water

molecules create mechanical

stress as they bond to the polymer, and this changes the film shape. The change caused by exposure to ultraviolet light is extremely rapid, of the order of 50

milliseconds, and this action could be repeated more than 10,000 times without deterioration of the film.[4-5]

Considerable

power was evident in the curling process. A film on a flat surface could jump to a one

centimeter height upon ultraviolet light induced curling, a distance ten thousand times the film thickness.[4-5] Such films have potential for environmental energy harvesting.[5-6]

References:

- Gaia Vince, "News Focus/Hydrology-Out of the Mist," Science, vol. 330, no. 6005 (November 5, 2010), pp. 750-751.

- Ben Gido, Eran Friedler, and David M. Broday, "Liquid-Desiccant Vapor Separation Reduces the Energy Requirements of Atmospheric Moisture Harvesting," Environ. Sci. Technol., Article ASAP (July 20, 2016), DOI: 10.1021/acs.est.6b01280.

- Harvesting water from air with less energy, American Chemical Society Press Release, July 20, 2016.

- Hiroki Arazoe, Daigo Miyajima, Kouki Akaike, Fumito Araoka, Emiko Sato, Takaaki Hikima, Masuki Kawamoto, and Takuzo Aida, "An autonomous actuator driven by fluctuations in ambient humidity," Nature Materials, advance online publication (July 18, 2016), doi:10.1038/nmat4693.

- Jens Wilkinson, "'Jumping film' harnesses the power of humidity," RIKEN Press Release, July 19, 2016.

- New film bends, straightens, jumps, and walks, using the power of humidity, YouTube Video, July 18, 2016.