Electromagnetic Shielding

October 17, 2016

Technology is driven by

consumer demand, and that's why

cellphones continue to evolve into the miraculous devices that we have today. It's said that the

Internet, and the previous technology of

video cassette players, advanced more quickly because of the demand for

pornography.

In the past, when endless

warfare was a way of life,

materials science was driven by the need for better

swords, and

shields as protection from them.

Prehistoric shields were made from

available materials, such as

wood and

animal hides, but they were

wrought from

metals as

metallurgy progressed (see figure).

Shortly after

radio waves were discovered, it was realized that it was sometimes necessary to

shield against them. Since an

electromagnetic wave is a combination of an

electric field and a

magnetic field, it can be

attenuated by shielding just one, or the other, of its components. The first effective shields

short-circuited the electric field component using a

Faraday cage, invented by

Michael Faraday in 1836. A Faraday cage is just a box formed from

conductive sheets or

wire mesh.

Faraday's

invention predated

Maxwell's electromagnetic theory of 1873 and the

generation and

detection of radio waves by

Heinrich Hertz in 1887. At its conception, the Faraday cage was designed to protect sensitive

electrical measurements from external

electric charge. After Faraday's time, the Faraday cage served as a shield for radio interference.

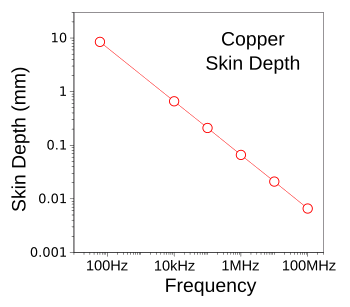

In most cases, you don't need that thick of a conductive material to have a Faraday cage. The well-known

skin effect describes the tendency of

alternating electric currents, such as those of radio waves, to have their highest

density at a conductor's

surface. Each conductor has a characteristic

skin depth at a given

frequency, and about two-thirds (1 - 1/

e) of electric currents are concentrated above that depth. The skin depth falls with frequency, and currents are attenuated to about 45

dBm below their surface values at ten skin depths.

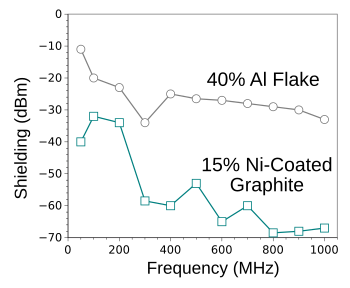

Magnetic materials will act as electromagnetic shields, with their effectiveness

scaling as the

square root of the

permeability. Materials such as

nickel that are both electrically conductive and magnetic offer both types of shielding in a single material (see graph). Because of their high permeability and low

coercivity,

ferrite materials are more effective than other magnetic materials at high frequencies.

Since

wireless devices have migrated to higher frequencies to attain a wider transmission

bandwidth for higher

data rates, the electromagnetic shielding

mantra for the thickness of an effective shield has become, "

How low can you go?".

Scientists at the

Korea Institute of Science and Technology (Seoul, Republic of Korea), the

University of Science and Technology (Daejeon, Republic of Korea), and

Drexel University (Philadelphia, Pennsylvania), have developed a

nanomaterial, a

thin film of

titanium carbide of a class of materials known as

MXenes, that acts as an effective electromagnetic shield.[2-4] MXenes get their name from their similarity to

graphene, an

archetypal 2-D material, since they are

two-dimensional metal

carbides and

nitrides.[2]

As

Babak Anasori, a

research assistant professor at Drexel and a

co-author of the

paper describing this research, explains

"As technology evolves and electronics become lighter, faster and smaller, their electromagnetic interference increases dramatically... Internal electromagnetic noise coming from different electronic parts can have a serious effect on everyday devices such as cell phones, tablets and laptops, leading to malfunctions and overall degradation of the device."[3]

While conventional shielding is effective, most such shields are heavy, and we all want our cellphones to be as light as possible.

Aerospace electronics requires shielding as well, and weight reduction is a prime aerospace consideration. The MXene material can be combined with a polymer solution and used as a

spray coating to add shielding to

component cases.[3]

The research team tested MXene shields in a thickness range from several

micrometers up to 45 micrometers in order to assess the thinnest films capable of shielding.[3] They found that micrometer thickness MXene films compete with aluminum and copper foils; and, at 8 micrometers, the MXene shields block 99.9999% of radiation (40 dBm attenuation) at cellphone frequencies, performance that requires

millimeter thickness

carbon composite sheets.[3] A 45 μm MXene film of Ti

3C

2 exhibited 92 dBm attenuation at these frequencies.[2]

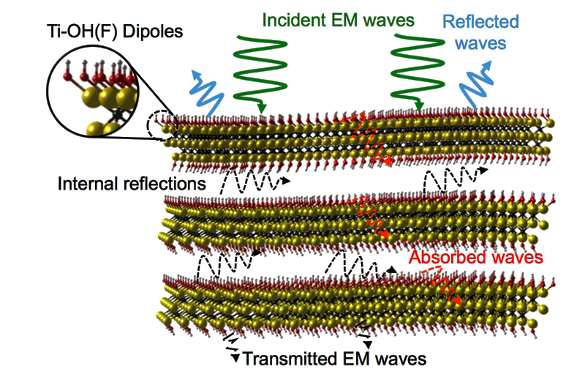

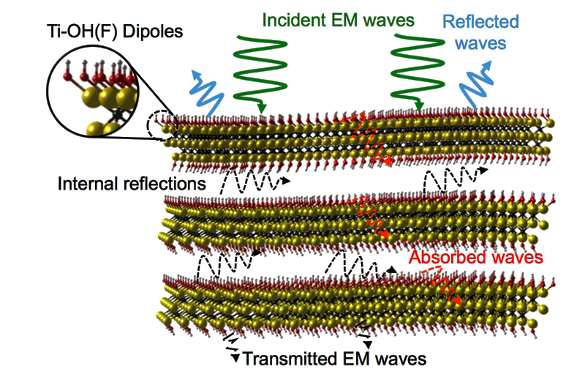

MXenes function so well as electromagnetic shields because of their high electrical conductivity (4600

siemens per

centimeter) and two-dimensional structure that allows a shield built from layers.[3] The layered structure allows multiple internal

reflections of the radiation, and these reflected waves are bounced around until they're

absorbed (see figure).[3] The

fundamental research of MXene properties was funded by the

National Science Foundation.[3]

|

| Shielding principle of the MXene layered structure. The structure absorbs and traps electromagnetic radiation. (Drexel University image.) |

References:

- David S. Dixon and James V. Masi, "Composite material for EMI/EMP hardening protection in marine environments," US Patent No. 5,066,424, November 19, 1991.

- Faisal Shahzad, Mohamed Alhabeb, Christine B. Hatter, Babak Anasori, Soon Man Hong, Chong Min Koo1, and Yury Gogotsi, "Electromagnetic interference shielding with 2D transition metal carbides (MXenes)," Science, vol. 353, no. 6304 (September 9, 2016), pp. 1137-1140, DOI: 10.1126/science.aag2421.

- Containing Our 'Electromagnetic Pollution,' Drexel University Press Release, September 8, 2016.

- Drexel's MXene Helps Contain 'Electromagnetic Pollution,' Drexel University YouTube Video, September 8, 2016.

- Drexel University MXenes Web Page.