Sponges of Boron Nitride

January 28, 2016

One of my first

scientific papers was published in the now defunct journal, High Temperature Science.[1] High Temperature Science, published from 1969-1991, was founded and

edited by the prolific

chemist,

John L. Margrave.[2] Margrave, who was elected to the

National Academy of Sciences in 1974, received his first degree in

physics from the

University of Kansas in 1948 after serving in the

US Army Signal Corps during

World War II.[2]

Margrave discovered that he was more interested in

chemistry, so he continued his

graduate education in chemistry at Kansas. Completing

experiments in

fluorine chemistry under high

temperature and high

pressure conditions, Margrave wrote a 300 page

dissertation and completed his

Ph.D. in just two years. After that, he worked as an

Atomic Energy Commission postdoctoral fellow under

Leo Brewer at the

University of California, Berkeley.[2] Brewer and

Kenneth Pitzer were

co-authors of the revision of a popular

thermodynamics textbook authored by

Gilbert N. Lewis and

Merle Randall.[3]

Margrave became an instructor in the chemistry department at the

University of Wisconsin-Madison in 1952, and much of his

research involved fluorine

bomb calorimetry.[2] In this technique, a useful complement to

oxygen bomb calorimetry, a substance is burned in a fluorine atmosphere so that its

heat of formation can be calculated. Margrave moved to

Rice University in 1963, a relocation perhaps facilitated by Kenneth Pitzer, who was the university

president at the time.

One principal theme of Margrave's research at Rice was

fluorination of

carbon compounds, principally the fluorination of

graphite to form "white graphite." This fluorinated graphite compound, known as

CFX, is an excellent

solid lubricant in

oxidizing and

corrosive environments at high temperature.[2] One of Margrave's students told me that they had fluorinated

peanut butter to see what would happen. Perhaps this was one of those unsanctioned experiments that students are known to do. Interestingly, Margrave was

co-inventor of an improved

embalming fluid.[4]

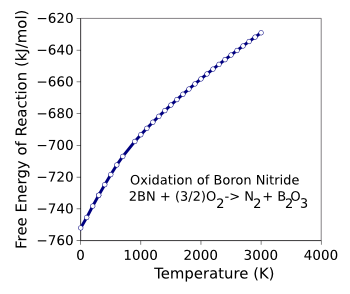

Boron nitride is another high temperature solid lubricant, since its

hexagonal polymorph has a layered structure like that of graphite. It's stable up to about 800

°C in

air, but only because its oxidation product,

boric oxide, forms a protective surface layer. As the calculated

free energy of the oxidation reaction shows, the oxidation to boric oxide is preferred in oxygen at all temperatures.[5] However, boron nitride is stable in

inert atmospheres,

vacuum, and

reducing atmospheres, up to about 2000°C.

Hexagonal boron nitride has another use.

Scientists at

Deakin University (Victoria, Australia),

Drexel University (Philadelphia, Pennsylvania), and the

Missouri University of Science & Technology (Rolla, Missouri) have created an

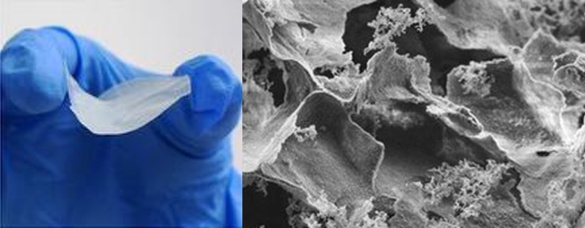

aerogel of boron nitride that functions as a

sponge for

oil.[6-9] The aerogel is formed from boron nitride

nanosheets.[6-9]

The boron nitride nanosheets, composed of just a few layers of hexagonal boron nitride, have a pore structure that allows absorption of more than 33 times their

weight in

organic solvents, such as oil.[6,8] The aerogels have a

density of just 1.4

mg/

cc, about 1,500 times less than the density of bulk boron nitride. These aerogels are formed as freestanding

membranes by

freeze-drying.[6] The

surface area per

gram is about the area of five and a half

tennis courts.[8-9]

The

2010 Gulf Coast oil spill had a reported cost of $40 billion.[9] Says Deakin University

professor and an

author of the

paper describing this research,

Ying Chen,

"Oil spills are a global problem and wreak havoc on our aquatic ecosystems, not to mention cost billions of dollars in damage... Everyone remembers the Gulf Coast disaster, but here in Australia they are a regular problem, and not just in our waters. Oil spills from trucks and other vehicles can close freeways for an entire day, again amounting to large economic losses... We are so excited to have finally got to this stage after two years of trying to work out how to turn what we knew was a good material into something that could be practically used."[8]

The research team developed an oil-absorbing boron nitride

powder in 2013, but a powder form is not suitable for oil

remediation. Says Deakin University's

Weiwei Lei, another member of the research team, "...you cannot simply throw powder onto oil – you need to be able to bind that powder into a sponge so that we can soak the oil up, and also separate it from water."[8] A one-step mechano-chemical process was used to

exfoliate the nanosheets from the hexagonal boron nitride and

functionalize them with

amino groups to create highly

water-dispersible particles.[6]

As another interesting

material property, the nanosheets show a strong blue

light emission under exposure to

ultraviolet light, in both their dispersed and dry states.[6] This research was supported by the

Australian Research Council.[9]

References:

- D.M. Gualtieri and P.J. Ficalora, Electron Transfer and Metallic Bonding: The Heats of Reaction of FeAl3-x(Ag;Zn;Pt;Au)x Alloys, High Temperature Science, vol. 7, pp. 25-36 (1975).

- James L. Kinsey, "Biographical Memoir-John Margrave, National Academy of Sciences, 2014.

- Gilbert Newton Lewis and Merle Randall, "Thermodynamics," Kenneth S. Pitzer and Leo Brewer, Eds., McGraw Hill (Second edition, 1961), 723 pp. (Amazon).

- James W. Campbell and John L. Margrave, "Embalming composition and method," US Patent No. 5,405,606, April 11, 1995 (Google Patents).

- NIST-JANAF Thermochemical Tables, US National Institute of Standards and Technology Web Site.

- Weiwei Lei, Vadym N. Mochalin, Dan Liu, Si Qin, Yury Gogotsi, and Ying Chen, "Boron nitride colloidal solutions, ultralight aerogels and freestanding membranes through one-step exfoliation and functionalization," Nature Communications, vol. 6, article no. 8849 (November 27, 2015), doi:10.1038/ncomms9849. This is an open access publication with a PDF file available here.

- Supplementary figures for ref. 6 .

- Drexel Materials Scientists Aid Australian Institution in Developing Super-Absorbent Material That Can Soak Up Oil Spills, Drexel University Press Release, November 30, 2015.

- Deakin scientists create revolutionary material to clean oil spills, Deakin University Press Release, November 30, 2015