Transparent Aluminum

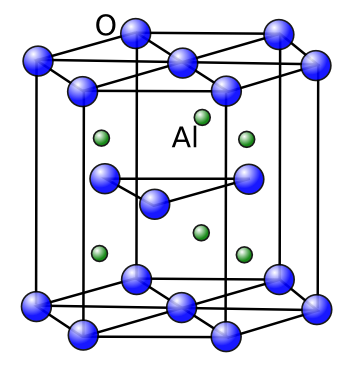

June 4, 2015 Among the many accomplishments of recently deceased Leonard Nimoy (March 26, 1931 - February 27, 2015) is directing credit for the fourth Star Trek Movie, "Star Trek IV: The Voyage Home." This movie is an unusual one in the Star Trek franchise, since it's very nearly a comedy. It certainly was popular, with gross receipts slightly more than $100 million, about four times the production cost.[1] As an example of comedy in this film, ship's engineer, Scotty, played by James_Doohan (March 3, 1920 - July 20, 2005), attempts to use a 1980s era desktop computer by talking into a mouse. After discovering that the computer will accept commands only via keyboard, he adeptly inputs the structure of "transparent aluminum" into a CAD program. Common aluminum, of course, is not transparent, so "transparent aluminum" must be aluminum modified in some way. One way to do this while still keeping the material chemically aluminum is to create a (fictional) allotrope. Just as the diamond allotrope of carbon is transparent while graphite is black, this fictional allotrope of aluminum could be transparent. Such an allotrope of aluminum does not exist, but we can still render aluminum transparent by combining it with other elements. Aluminum oxynitride and the sapphire crystalline form of aluminum oxide are both transparent. Sapphire is commonly used as a watch crystal. | The arrangement of atoms in a unit cell of sapphire. Sapphire has trigonal crystal structure, represented by the hexagonal cell shown. The space group is designated R3c (Illustration by the author using Inkscape.) |

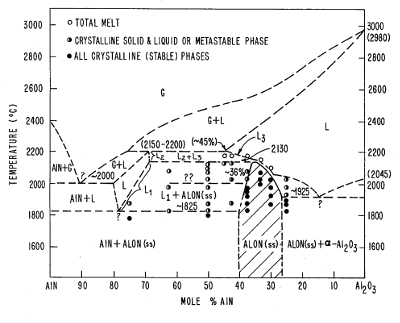

| Phase Diagram of the aluminum nitride-aluminum oxide system, showing the phase region of aluminum oxynitride. Click for larger image. (Via Google Patents.)[3] |

|

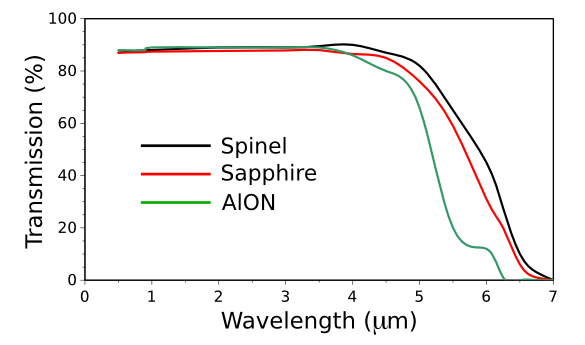

| Optical transmission of sapphire, aluminum oxynitride, and spinel. The mid-infrared transmittance of spinel allows its use as a protective window for lasers. (Graphed by the author from available data using Gnumeric.) |

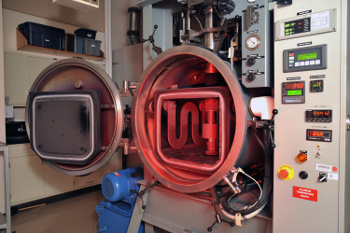

"A big problem with growing crystals is that you have to melt the starting powder at very high temperatures, over 2000 degrees Celsius... the molten material reacts with the crucible, and so if you're trying to make very high quality crystals, you end up [with a] huge amount of defects."[4]Instead, NRL used a sintering aid - a "glue" that helps stick solid ceramic particles together - and hotpressed the materials at a lower temperature in a vacuum. This process is limited only be the size of your press, so it's scalable to very large pieces. The NRL team was able to make transparent pieces up to eight inches in diameter in their own laboratory using the equipment shown in the photograph.[4]

| Hotpress and vacuum chamber used for making transparent spinel windows. (Photograph by Jamie Hartman, U.S. Naval Research Laboratory.) |

|

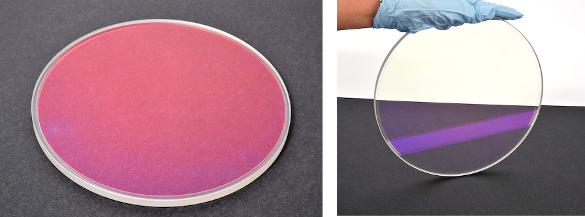

| The "green state" of the spinel precursor is actually pink, as the left image shows. The right image is an example of the final transparent spinel product. (left and right photographs by Jamie Hartman, U.S. Naval Research Laboratory) |

References:

- Star Trek IV: The Voyage Home (1986, Leonard Nimoy, Director) on the Internet Movie Database.

- Normand D. Corbin, "Aluminum oxynitride spinel: A review," Journal of the European Ceramic Society, vol. 5, no. 3 (1989), pp. 143-154.

- James W. McCauley and Normand D. Corbin, "Process for producing polycrystalline cubic aluminum oxynitride," US Patent No. 4,241,000 (December 23, 1980).

- Kyra Wiens, "Transparent Armor from NRL; Spinel Could Also Ruggedize Your Smart Phone," Naval Research Laboratory Press Release, April 23, 2015.