Low Refractive Index

November 16, 2015

I just got a new pair of

eyeglasses. Unlike my old pair, which used

lenses ground from

glass, this new pair has

plastic lenses. Although I don't know the specific plastic used for the lenses,

polycarbonate is representative of such

materials, and it has a low

density (1.22

g/

cc) with a high

refractive index (1.585) that makes it easier to

figure a lens.

Optical crown glass, a traditional lens material, also has a high refractive index (1.523), but it's much heavier, having a density of 2.55 g/cc. My new eyeglasses are much lighter than the old, since the density of the plastic is half that of glass. My new eyeglasses have

progressive lenses, a

bifocal lens technology with a smooth transition between distance and reading aspects.

While high refractive index is useful for lens making, low refractive index optical materials are also useful.

Optical fiber is an example of an optical element combining a low refractive index material with high refractive index material. Two useful optical elements making use of both low and high refractive index materials are the

dielectric mirror and the

dichroic filter.

Whenever

light passes through an interface of one refractive index to another, a portion of the light will be

reflected, and the rest will be transmitted. By selecting the thickness of multiple refractive layers, the reflected rays can be selected to

interfere constructively or destructively at certain

wavelengths. This is an optical manifestation of

Bragg's law.

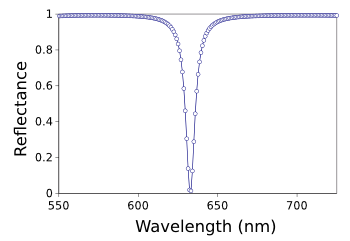

Modern

material deposition techniques make it easy to produce optical films of many layers. I designed a

bandpass filter for the

helium-neon laser wavelength (632.8 nm) using alternating layers of materials with refractive indices of 1.49 and 2.38. This filter has 40 double layers with a layer thickness of 106.17 nm for the lower refractive index and 66.47 nm for the higher refractive index. The filter response at

normal incidence is shown below.

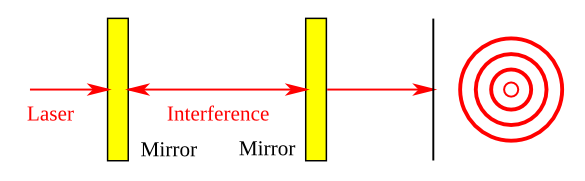

The lowest refractive index is 1.0, the refractive index of the

vacuum, but the refractive index of

air, about 1.0003, is close enough to one that 1.0 is often used in calculations. When an air gap is formed between two

parallel plates of high refractive index, this

Fabry–Pérot etalon will cause an

interference pattern through

constructive and destructive interference of light waves of a particular wavelength. Although any interface between media of different refractive indices will lead to

reflection (4% in the case of

window glass), such etalons perform best with partially-transmitting

mirrors (see figure).

Construction of an air gap between parallel plates is easy when the plates are thick, like

microscope slides. Thin plates would likely

deform, so the parallelism is destroyed. It would be far easier to work with an optical material with a refractive index very close to 1.0.

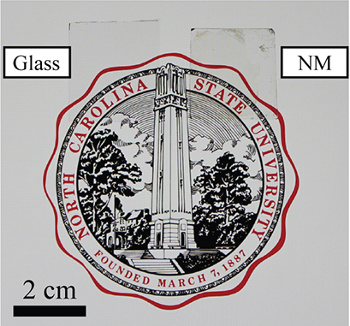

That was the motivation for recent

research by

scientists from

North Carolina State University (NCSU, Raleigh, North Carolina) and the

Air Force Research Laboratory (Dayton, Ohio). In a recent

paper in

Advanced Functional Materials, they describe a

nanolattice material with a refractive index as low as 1.025.[2-3] As is typical in

science, this recent advance is built on a previous process, developed by the NCSU scientists last year.[4-5]

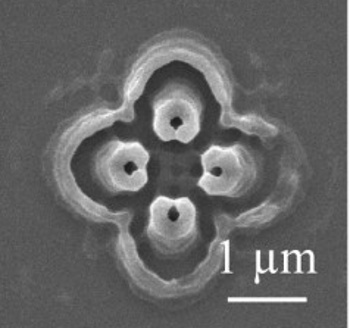

The NCSU process creates a sea of

self-assembled colloidal particles on surfaces. In last year's study, such an assemblage was placed on a

photosensitive layer to act as lenses for selective exposure.[4-5] Says

Chih-Hao Chang, an

assistant professor of

mechanical and aerospace engineering at NCSU,

"We are using the nanosphere to shape the pattern of light, which gives us the ability to shape the resulting nanostructure in three dimensions without using the expensive equipment required by conventional techniques... and it allows us to create 3-D structures all at once, without having to make layer after layer of 2-D patterns."[5]

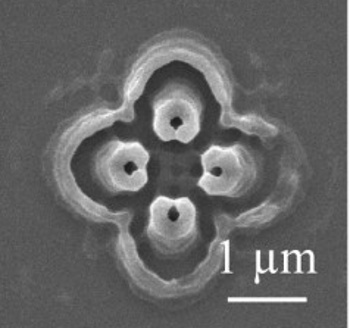

| An example of an asymmetric hollow-core three-dimensional nanostructure fabricated by shining light through a surface nanoparticle lens array.

(NCSU image by Xu Zhang.)[5] |

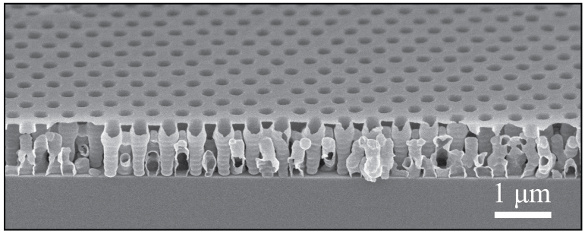

The surface nanoparticles were used to create ordered nanostructured layers in a different way to create the low refractive index films. The surface array acts as a

template for formation of a thin layer of

aluminum oxide by

atomic layer deposition (ALD). The polymer surface array is then

burned off, and a three-dimensional aluminum oxide coating is left behind.[3]

Explains

Xu Zhang, lead author of the recent paper and a

Ph.D. student at NCSU,

"The key to the film's performance is the highly-ordered spacing of the pores, which gives it a more mechanically robust structure without impairing the refractive index. We are able to control the thickness of the aluminum oxide, creating a coating between two nanometers and 20 nanometers thick... Using zinc oxide in the same process, we can create a thicker coating. And the thickness of the coating controls and allows us to design the refractive index of the film."[3]

The research team has developed a

mechanically stiff aluminum oxide film with a refractive index of 1.025.[3] Aside from optical applications, these films can serve as

electrical insulators in

high speed interconnections in

integrated circuits. Says Chang, "The steps in the process are potentially scalable, and are compatible with existing chip manufacturing processes... Our next steps include integrating these materials into functional optical and electronic devices."[3]

References:

- Pliny the Elder, "The Natural History," John Bostock, Trans., Book 37, Chap. 16 ("Smaragdus"), via Project Perseus.

- Xu A. Zhang, Abhijeet Bagal, Erinn C. Dandley, Junjie Zhao, Chrisopher J. Oldham, Gregory N. Parsons and Chih-Hao Chang, "Ordered Three-Dimensional Thin-Shell Nanolattice Materials with Near-Unity Refractive Indices," Advanced Functional Materials, October 12, 2015, doi: 10.1002/adfm.201502854.

- Matt Shipman, "Dielectric Film Has Refractive Index Close to Air for Photonics Applications," North Carolina State University Press Release, October 12, 2015.

- Xu A. Zhang, Bin Dai, Zhiyuan Xu and Chih-Hao Chang, "Sculpting Asymmetric Hollow-Core Three-Dimensional Nanostructures Using Colloidal Particles," Small, December 8, 2015, DOI: 10.1002/smll.201402750.

- Matt Shipman, "Nanoparticle Allows Low-Cost Creation of 3-D Nanostructures," North Carolina State University Press Release, December 8, 2014.