Playing Archived Audio

November 19, 2015

Some of our early

audio history is contained on

film soundtracks, but most is contained on

mechanical recordings known as

phonograph records. The

materials technology for phonograph records progressed to the point at which

vinyl became the preferred medium, since it was durable and easily

hot-stamped by a

metal die to

mass-produce recordings.

While these

phonograph records were intended to be played by running a

stylus through the record "groove," this mechanical operation eventually degrades the recording, especially when the stylus is

worn or pressed with too much

force. This leads to a dilemma for

archivists, who want to make the content of these recordings accessible, while at the same time preserving them for later

generations.

Modern technology has a way of making some "impossible" tasks very easy to do, and it wasn't long before

optical techniques were developed that allow the non-contact playback of phonograph recordings. I wrote about one such method for playback to audio recorded on

tin cylinders in an

earlier article (His Master's Voice, August 15, 2011).

The

laser, in my

opinion the greatest optical

invention after the

lens, is one technology used for non-contact playback of vinyl records. The lens dates from

antiquity, and a "

burning glass" is even mentioned in

Aristophanes' play,

The Clouds (424 BC).

|

Strepsiades:

Have you ever seen this stone in the chemist's shops, the beautiful and transparent one, from which they kindle fire?

Socrates:

Do you mean the burning-glass?

|

In 1977, during the time I was a member of the

Audio Engineering Society, William K. Heine presented a paper on a

laser-based phonograph at its

57th convention in

Los Angeles. This was before the invention of the

semiconductor laser, so the laser used in Heine's system was the once ubiquitous

helium-neon laser.

Early attempts at development of a

consumer-grade laser phonograph, notably by

Finial Technology, revealed a problem common to all optical systems; namely, the affects of

dust and

dirt. While a conventional stylus player just moves such debris aside, the laser turntable registered them as an audible "click."

It wasn't until 1997 that a viable laser phonograph was produced, the

ELP LT-1XA Laser Turntable, a system using five lasers. A different type of non-contact phonograph playback uses

imaging technology and

computer processing. This system, called

IRENE, is being developed at

Lawrence Berkeley National Laboratory.

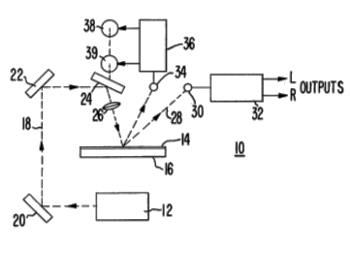

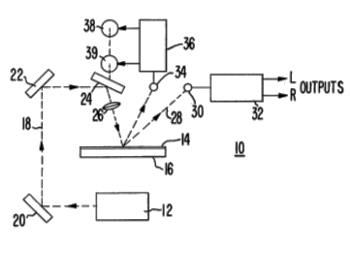

| Fig. 1 of US Patent No. 3,992,593, "Disc phonograph record playback by laser generated diffraction pattern," by William K. Heine, November 16, 1976.

(Via Google Patents.)[3] |

By the mid-

20th century,

engineers had the idea that

sound could be recorded on a

magnetic material deposited on a non-magnetic

tape. The

tape recorder was an improvement on earlier

magnetic wire recorders. Tape recorders had much higher fidelity, since the

magnetic domains, the smallest packets of sound

intensity, were the very small

powder particles on the tape, while the domains in the wires were the typical large domains found in bulk materials.

The two major forces in early magnetic sound recording were

Ampex, which produced the recording and playback equipment, and

Minnesota Mining and Manufacturing Company (now, 3M) producing the magnetic tape. The 1947 success of

Bing Crosby in using magnetic tape and

post-production editing technology in

radio broadcasting

created a huge market for tape recording in the radio and recording industries.

| Two-inch wide magnetic tape was used in the SoundScriber, a machine that recorded 24 hours of low-quality audio on a single reel.

(Photo by the author, via Wikimedia Commons.) |

Between that time and the advent of

digital audio, just about every sound recording was a tape recording, and just as the movie studios needed to maintain

controlled-environment vaults to archive their films, recoding studios and broadcasters needed similar vaults for their massive piles of audio tape. Safe storage conditions are considered to be 20

°C

and 40%

relative humidity, although one

ISO standard (TR 6371-1989) recommends a lower humidity of 20%.[4]

One interesting magnetic problem associated with archived magnetic tape is "

print-through," in which a faint magnetic image from a layer of tape on a reel is imprinted on an adjacent layer. This is only a problem because of the wide

dynamic range of the

human ear (120 dB, but that covers the range from the

threshold of hearing to experiencing

pain).

Print-through was a minor nuisance, but the recording tape, as a material, was not thought to present any problems. The carrier tape was

mylar, a material with excellent

mechanical properties for tape recording, and the magnetic particles are

ferric oxides (sometimes with additional

elements, such as

chromium) with high

hardness.

What turned out to be the problem was the

polyester-

urethane material used to bind the oxide particles to the mylar. It was a shock to audio engineers when they attempted to play some of their priceless archived recordings and the magnetic layer was plowed off the mylar backing tape by the

playback head. This subsequently named, "sticky-shed syndrome," also fouled the tape recorder mechanism, and that needed to be cleaned before other tapes could be played.

Engineers are inventive, and they eventually found a way to overcome sticky-shed, albeit for the limited time it took to transfer the audio from a sticky-shed tape to fresh media.

baking tapes in a dry

oven at about 120-140

°F for periods up to two days, stopped sticky-shed for a few weeks. The purported reason why baking works is that it drives out some of the

water that reacted with the

polymer binder during years of storage in a humid environment.

This baking technique was transmitted by

social media connections between audio engineers in the early days of the problem. Although it works, heating an important audio tape is not something you would want to do unless it was really necessary; but, how would you know it was necessary, unless the tape does exhibit sticky-shed and is damaged upon playing?

Chemists at the

University of South Carolina (Columbia, South Carolina) have teamed with an archivist at the

Preservation Research and Testing Division of the

US Library of Congress to investigate a minimally invasive method for differentiating sticky-shed

quarter-inch audio tapes from playable tapes. Their

research is reported in a recent issue of the

American Chemical Society journal,

Analytical Chemistry.[5-6]

There's considerable motivation for such research. The

public policy organization,

Heritage Preservation, estimates that there are more than 46 million archived sound in the

United States alone.[5-6] Since the degradation mechanism appears to be

hydrolysis of the polyester in which water from humid air splits the compound into an

alcohol and a

carboxylic acid.[6] The research team reasoned that such a change should be visible using

infrared spectroscopy.[6]

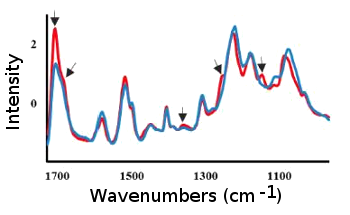

They used a surface infrared technique,

attenuated total reflectance Fourier-transform infrared spectroscopy, to examine a batch of 133 reel-to-reel audiotapes from the Library of Congress

Motion Picture Broadcasting and Recorded Sound Division. Individual reels from this match had been classified as either playable or sticky-shed by audio engineers. All reels in this lot were probably made by a single manufacturer.[6]

Classification of the infrared spectra was done using

principal component analysis,

quadratic discriminant analysis, and

K-means cluster analysis. Nonplayable tapes had enhanced peak intensities at various

wavenumbers (see figure). such an analysis successfully identified 93.78% of nonplayable tapes in the

calibration set and 92.31% of nonplayable tapes in a subsequent test set.[5]

Says

Stephen Morgan, a professor of

chemistry at the University of South Carolina and an author of the research paper,

"This gives archivists a way to triage the tapes that they have... They can identify the ones that can be immediately digitized, and they don't do anything that harms any of them in the process."[6]

| An article on this topic is enough of an excuse to publish this photograph, taken during my college radio days, c. 1967.

(Photo from author's archive, modified using GIMP.) |

References:

- Aristophanes, "The Clouds," F.W. Hall and W.M. Geldart, eds., (Greek text via Project Perseus).

- Aristophanes, "The Clouds," William James Hickie, Trans., Project Gutenberg.

- William K. Heine, "Disc phonograph record playback by laser generated diffraction pattern," US Patent No. 3,992,593, November 16, 1976 (via Google Patents).

- John W.C. Van Bogart, "Magnetic Tape Storage and Handling - A Guide for Libraries and Archives," National Media Laboratory, June 1995, Chap. 5.

- Brianna M. Cassidy, Zhenyu Lu, Nathan C. Fuenffinger, Samantha M. Skelton, Eric J. Bringley, Linhchi Nguyen, Michael L. Myrick, Eric M. Breitung, and Stephen L. Morgan, "Minimally Invasive Identification of Degraded Polyester-Urethane Magnetic Tape Using Attenuated Total Reflection Fourier Transform Infrared Spectroscopy and Multivariate Statistics," Anal. Chem., vol. 87, no. 18 (August 14, 2015), pp, 9265-9272, DOI: 10.1021/acs.analchem.5b01810.

- Steven Powell, "Born to run off the reels," University of South Carolina Press Release, October 14, 2015.