Diamond Thread

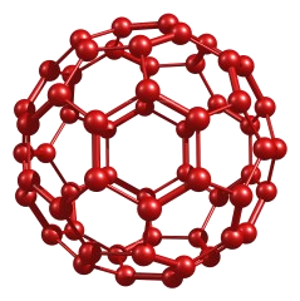

October 15, 2014 The expression, "tough as nails," is flawed in two respects. First, the word, "tough," in this expression is used to connote hardness or yield strength, while materials scientists reserve toughness to express fracture strength. The science of fracture toughness, which I wrote about in a previous article (Atmospheric Dust, February 2, 2011), was pioneered by Alan Arnold Griffith. In 1921, Griffith proposed a fracture law that relates the ultimate strength of a brittle solid to the size of its largest flaw. Second, while the strength of the steel from which nails are made is considerable, steel is not a strong as some materials. Young's modulus, which is a measure of how a material will deform when stress is applied, is about 200 GPa for steel. Diamond has a Young's modulus of 1,220 GPa, but stronger still is another allotrope of carbon, carbyne (linear acetylenic carbon), that is predicted to have a Young's modulus as high as 32,000 GPa. I wrote about carbyne in a previous article (Carbyne, August 28, 2013). Intermediate in scale between carbyne and diamond is another carbon allotrope, fullerene, exemplified by the sixty-carbon atom, ball-shaped molecule, buckminsterfullerene, C60, as shown in the figure. Although this molecule in its natural state is soft, like graphite, aggregates of buckminsterfullerene, called fullerite, become harder than diamond when compressed. Considerable research on this material has been conducted by Mikhail Popov, V. Blank, and their colleagues at various Institutions in Moscow, Russia.[1-3], most recently, this year.[4-5] Fullerite has an isothermalbulk modulus of 491 GPa, as compared with about 445 GPa for diamond. | Diagram of buckminsterfullerene, C60. (Moscow Institute of Physics and Technology State University image.)[5] |

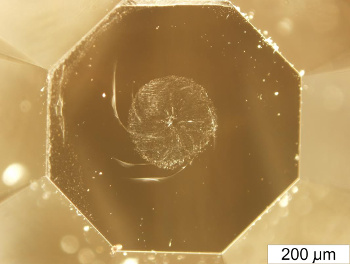

| Diamond anvil damaged during synthesis of ultrahard fullerite. (Moscow Institute of Physics and Technology State University image by Mikhail Popov.)[5] |

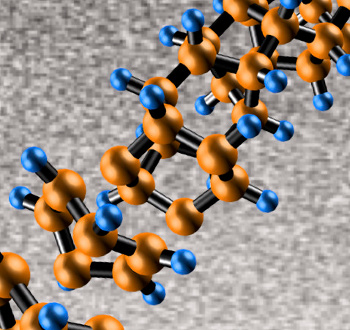

“The discovery described in this article (the catalytic synthesis of ultrahard fullerite) will create a new research area in materials science because it substantially reduces the pressure required for synthesis and allows for manufacturing the material and its derivatives on an industrial scale."[5]Instead of making bulk fullerite, scientists from Pennsylvania State University (University Park, Pennsylvania), the Carnegie Institution of Washington (Washington DC), and Arizona State University (Tempe, Arizona), have instead made diamond-like threads of carbon polymer.[6-8] These nanothreads are long, thin strands of carbon atoms having the same bonding arrangement as the diamond structure in which each carbon atom is tetrahedrally-coordinated with the others. High pressure applied to benzene forms cyclohexane rings of six carbon atoms bonded together, and these rings are bonded to each other (see figure). The edge bonds are terminated by hydrogen.[7]

| Artist's impression of the structure of a diamond nanothread. It's a chain of cyclohexane molecules with hydrogen atoms shown in blue. (Penn State University image by Enshi Xu.) |

"From a fundamental-science point of view, our discovery is intriguing because the threads we formed have a structure that has never been seen before... It is as if an incredible jeweler has strung together the smallest possible diamonds into a long miniature necklace... Because this thread is diamond at heart, we expect that it will prove to be extraordinarily stiff, extraordinarily strong, and extraordinarily useful."[7]To create these diamond threads, the research team compressed a six millimeter diameter column of benzene. Slow release of pressure after room temperature compression allowed the carbon atoms to link up in a highly ordered chain of the cyclohexane molecular units.[7] During compression, the flat benzene molecules first stack together, then they bend and break apart. As the pressure is released, the carbon atoms reconnect into the diamond nano-thread structure.[7] X-ray and neutron diffraction, Raman spectroscopy, solid-state NMR, transmission electron microscopy and first-principles calculations confirmed the structure, which is crystalline in two dimensions.[6] It has short-range order in the other dimension, but portions of these diamond nanothreads are less than perfect.[6-7] It's conjectured that the carbon atoms in the benzene molecules, after having their original bonding destroyed, bond differently as pressure is removed, so a polymerization occurs to form the diamond nanothread structure.[7] Since the thread width is atomically small, such threads could potentially become an important lightweight, strong, stiff material.[7] Says Badding,

"You can attach all kinds of other atoms around a core of carbon and hydrogen. The dream is to be able to add other atoms that would be incorporated into the resulting nanothread. By pressurizing whatever liquid we design, we may be able to make an enormous number of different materials... One of our wildest dreams for the nanomaterials we are developing is that they could be used to make the super-strong, lightweight cables that would make possible the construction of a space elevator, which so far has existed only as a science-fiction idea."[7]This research was funded by the U.S. Department of Energy.[7]

References:

- V. Blank, M. Popov, S. Buga, V. Davydov, V. N. Denisov, A. N. Ivlev, B. N. Mavrin, V. Agafonov, R. Ceolin, H. Szwarc, and A. Rassat, "Is C 60 fullerite harder than diamond?" Physics Letters A. vol. 188, no. 3 (May 23, 1994), pp. 281-286.

- V. D. Blank, S. G. Buga, N. R. Serebryanaya, G. A. Dubitsky, B. Mavrin, M. Yu. Popov, R. H. Bagramov, V. M. Prokhorov, S. A. Sulynov, B. A. Kulnitskiy and Ye. V. Tatyanin, "Structures and physical properties of superhard and ultrahard 3D polymerized fullerites created from solid C60 by high pressure high temperature treatment.," Carbon, vol. 36, nos. 5-6 (1998), pp. 665-670.

- V. Blank, M. Popov, G. Pivovarov, N. Lvova, K. Gogolinsky, and V. Reshetov, "Ultrahard and superhard phases of fullerite C60 : comparison with diamond on hardness and wear," Diamond and Related Materials, vol. 7, nos. 2-5 (February, 1998), pp. 427-431.

- M. Popov, V. Mordkovich, S. Perfilov, A. Kirichenko, B. Kulnitskiy, I. Perezhogin, and V. Blank, "Synthesis of ultrahard fullerite with a catalytic 3D polymerization reaction of C60," Carbon, vol. 76 (September, 2014, doi: 10.1016/j.carbon.2014.04.075), pp. 250-256.

- Scientists come closer to the industrial synthesis of a material harder than diamond, Moscow Institute of Physics and Technology State University Press Release, September 15, 2014.

- Thomas C. Fitzgibbons, Malcolm Guthrie, En-shi Xu, Vincent H. Crespi, Stephen K. Davidowski, George D. Cody, Nasim Alem, and John V. Badding, "Benzene-derived carbon nanothreads," Nature Materials, Advance Online Publication (September 21, 2014, doi:10.1038/nmat4088).

- Scientists use 'smallest possible diamonds' to form ultra-thin nanothreads, Penn State University Press Release, September 22, 2014.

- John Badding, professor of chemistry at Penn State, talks about his research, YouTube Video by Penn State University, September 21, 2014.