Ammonia Synthesis

September 15, 2014 The household chemical that everyone knows as "ammonia" is not really ammonia, NH3. It's the solution of ammonia, which is a gas, in water, forming ammonium hydroxide, NH4OH. Ammonium hydroxide is not easily isolated, so its only existence is as [NH4]+ and [OH]- in the water solution. One possible reason to quit smoking is that ammonium hydroxide is purposely added to some tobacco products. You'll be surprised to see the long list of such tobacco additives.[1] Although household ammonia is a popular item among kitchen chemists, all chemistry has its precautions. Household ammonia should never be mixed with household bleach, or cleaning products containing bleach, since these will react to form nasty chemicals. Household bleach is sodium hypochlorite, NaClO, so one possible reaction, after a chain of prior dissociations, is2NH3 + Cl2 → 2NH2ClThe product of this reaction, NH2Cl, chloramine, is a respiratory irritant which damages mucous membranes, and it may also be carcinogenic. One compound of ammonia, ammonium nitrate, NH4NO3, is an important fertilizer because of its high nitrogen content. One incidental use, as shown in the photograph, is as a component of instant cold packs, since the hydration of the salt (mixing with water) is endothermic, consuming 26.2 kJ/mole of heat. It's also used as an explosive and as a component of explosives.

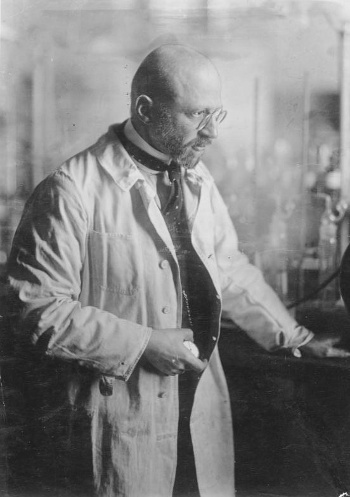

| I received this ammonium nitrate cold pack from a dentist after some minor oral surgery. The pack contains a pouch of water that wets the ammonium nitrate when it's broken. The hydration of ammonium nitrate is endothermic, drawing heat from the environment (i.e., my cheek). (Photograph by the author.) |

HNO3 + NH3 → NH4NO3Haber's process was developed to an industrial scale by Carl Bosch, so the process is commonly known as the Haber-Bosch process. Haber received the 1918 Nobel Prize in Chemistry for "for the synthesis of ammonia from its elements," while Bosch needed to wait until 1931 for his Nobel Prize. Science,[2] 120 million tons of nitrogen are annually extracted from the air in its production as a precursor to fertilizer production. About two percent of the world's energy is used to produce ammonia, and the market for ammonia is expected to exceed $100 billion in 2019.[2] There is, however, a dark side to ammonia. Although there's plenty of nitrogen in the atmosphere available for the synthesis of NH3, the hydrogen comes from natural gas. Ammonia synthesis consumes 5% of the world's natural gas, and it pumps hundreds of millions of tons of carbon dioxide into the atmosphere as a byproduct.[2] That's why a team of chemists at George Washington University (Washington, D.C.) was inspired to find an alternative to the Haber-Bosch process.[2-4] This research was inspired by the operation of fuel cells that generate electricity by dissociating ammonia into nitrogen and hydrogen.[2] These fuel cells use a molten mixture of potassium hydroxide and sodium hydroxide as an electrolyte, so the George Washington University team decide to test this electrolyte in the reverse reaction; that is, synthesizing ammonia from its elements. Water was used as the hydrogen source.[2-4] The process still requires the traditional iron catalyst, in this case a nanoscale iron oxide suspended in the molten salt. One problem area is that this catalyst is only stable for a few hours.[3] At the temperatures involved, the water is in the form of steam.[3] With application of an electrical current, the iron oxide nanoparticles become electron-rich, and the water and nitrogen combine at their surface to form ammonia.[3-4] The electrolyte is a 50:50 (by mole) mix of potassium hydroxide and sodium hydroxide. At 200°C, ammonia is produced at 1.2 volts and less than two milliamps per square centimeter. Increasing the temperature to 250°C and running at a pressure of 25 bar to contain the steam decreases the voltage to 1.0 volt at the same current.[3] Either of these conditions is milder than that of the Haber-Bosch process, 450°C and 200 bar.[4] The coulombic efficiency of the process is 35%; that is, 35% of the applied current results in the formation of ammonia molecules.[3] Chemists still have a way to go to mimic nature for extraction of nitrogen from the air. Nitrogen-fixing bacteria do this at room temperature.[4]

| Bocci Ball, anyone? If we could see an ammonia molecule, it would look somewhat like this, but quite a bit fuzzier. (Via Wikimedia Commons.) |

References:

- Ingredients Added To Tobacco, Philip Morris USA.

- Robert F. Service, "New recipe produces ammonia from air, water, and sunlight," Science, vol. 345 no. 6197 (August 8, 2014), p. 610.

- Stuart Licht, Baochen Cui, Baohui Wang, Fang-Fang Li, Jason Lau, Shuzhi Liu, "Ammonia synthesis by N2 and steam electrolysis in molten hydroxide suspensions of nanoscale Fe2O3," Science, vol. 345 no. 6197 (August 8, 2014), pp. 637-640.

- Jake Jacobs, "Water and air are all you need to make ammonia—one of world's most important chemicals" Phys.org, August 8, 2014.