Spider Silk Mechanics

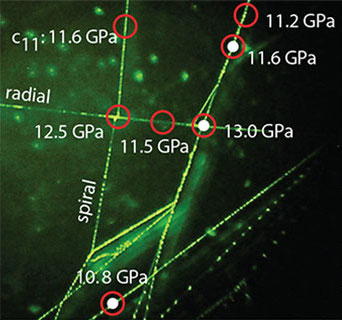

February 15, 2013 Mechanical testing of materials is a routine laboratory activity. It's become so easy that nearly as much effort is needed to archive and analyze the results as to do the actual experiments. ASTM International, formerly known as the American Society for Testing and Materials, has published standard methods for material testing. ASTM was founded more than a century ago to address the pressing need to certify steel for railroad rails. Carbon nanotubes and spider silk are the preeminent high strength materials of the past few decades. I've written about both of these, most recently about spider silk, here (Spider Silk, March 12, 2012). The tensile strength of spider silk (1.3 GPa) is nearly as large as that of high grade steel. It achieves this with a density (1.3 g/cc) that's one-fifth as large, and spider silk has a higher mechanical toughness. Such high strength derives from spider silk's mixed molecular structure in which hard, crystalline regions of alanine are joined by amorphous and elastic glycine linkages. There have been attempts to synthesize analogous material by chemical means, but the properties of these materials are not as good. Not surprisingly, there have been experiments in using genetic engineering to produce spider silk in bacteria and silkworms.[1-2] Accurate measurements are required in any research and development project because you can't improve what you can't measure. Mechanical measurements other than the simple stress-strain curve on spider silk materials are difficult because of the small size of the silk strands. To improve such measurements, a research team from the Department of Chemistry and Biochemistry, Arizona State University (Tempe, Arizona) has investigated property determination of spider silk by Brillouin light scattering. The results of their research have been published in a recent issue of Nature Materials.[3-4] Léon Brillouin is known to crystallographers for the Brillouin zone, and in quantum mechanics for the Wentzel–Kramers–Brillouin approximation, best known as just WKB. Brillouin analyzed the scattering of light that arises from the density variation in the refractive index of a material. In the modern form of this experiment, a laser induces acoustic waves in the material, and a spectrometer analyzes the scattered light to determine the material strain.[4] Lead author of the study, Kristie J. Koski, who is now a postdoctoral fellow in the Department of Materials Science and Engineering, Stanford University, developed Brillouin light scattering techniques that enabled the non-invasive, non-destructive determination of the mechanical properties of a spider web as created by a spider.[4] The measurements included all five elastic constants in the stiffness tensor, and also the refractive indices, and longitudinal and transverse sound velocities for silk of the spiders, Argiope aurantia, Latrodectus hesperus, Nephila clavipes and Peucetia viridans.[3] The Brillouin light scattering measurements reveal the linear elastic response for all possible deformations (e.g., compression, shear), which goes far beyond the result of a stress–strain test. The stiffness tensor also revealed a negative Poisson's ratio.[3] The technique allowed a spatial mapping of the elastic stiffness, as shown in the figure. | The experimentally measured value of the elastic constant, C11, for various portions of a pristine spider web. The solid white circles are "glue/goo" spots. (Stanford University image by Kristie Koski.) |

"The possibility of adjusting mechanical properties by simply adjusting water content is interesting from a bio-inspired mechanical structure perspective and could lead in interesting research directions as we try to invent new fibers."[4]

| Kristie J. Koski. Note the proper laboratory safety attire, which includes safety glasses, protective gloves, and a lab coat. (Stanford University photograph by Judy J. Cha.) |

References:

- Xiao-Xia Xia, Zhi-Gang Qian, Chang Seok Ki, Young Hwan Park, David L. Kaplan and Sang Yup Lee, "Native-sized recombinant spider silk protein produced in metabolically engineered Escherichia coli results in a strong fiber," Proc. Natl. Acad. Sci., vol. 107, no. 32 (August 10, 2010), pp. 14059-14063.

- Florence Teulé, Yun-Gen Miao, Bong-Hee Sohn, Young-Soo Kim, J. Joe Hull, Malcolm J. Fraser, Jr., Randolph V. Lewis and Donald L. Jarvis, "Silkworms transformed with chimeric silkworm/spider silk genes spin composite silk fibers with improved mechanical properties," Proc. Natl. Acad. Sci., vol. 109, no. 3 (January 17, 2012), pp. 923-928.

- Kristie J. Koski, Paul Akhenblit, Keri McKiernan and Jeffery L. Yarger, "Non-invasive determination of the complete elastic moduli of spider silks," Nature Materials, Published Online, January 27, 2013, doi:10.1038/nmat3549.

- Andrew Myers, "Stanford Researcher Sheds New Light on the Mysteries of Spider Silk, Stanford University Press Release, February 4, 2013.

- Florence Teulé, Yun-Gen Miao, Bong-Hee Sohn, Young-Soo Kim, J. Joe Hull, Malcolm J. Fraser, Jr., Randolph V. Lewis and Donald L. Jarvis, "Silkworms transformed with chimeric silkworm/spider silk genes spin composite silk fibers with improved mechanical properties," Proc. Natl. Acad. Sci., vol. 109, no. 3 (January 17, 2012), pp. 923-928.