Strong Nano Trusses

September 25, 2013 The IBM Selectric typewriter was the standard word processing tool when I first entered science. I typed my dissertation on a rented Selectric II, and the drafts of my first published papers were typed on Selectrics. About 13 million Selectrics of all types were sold through 1986. I wrote an article about the Selectric on the occasion of its fiftieth anniversary (IBM Selectric Typewriter, August 3, 2011). The Selectric was especially useful for scientific manuscripts, since it could type mathematical symbols. This was possible, since the Selectric didn't use the massive array of type bars of traditional typewriters which limited the maximum number of possible characters. The Selectric used an interchangeable type ball. The surface of these balls was covered with the same impact characters found on the type bars. A particular character was selected by rotation and tilting of the ball to its position, followed by impact. The mathematical symbols were available by removing the type ball of alphabetic characters and inserting the math ball. It was a tedious process, but it gave employment to many secretaries. The math ball would need to be inserted quite often for some papers, so type balls were often dropped. Occasionally, a type ball wouldn't work properly after being dropped because one of its index teeth, which were used to mechanically align the ball for perfect spacing, had broken off. I'm fairly sure that I wasn't the first to notice that the breakage was always at the tooth beneath an underscore or dash character (see figure). | The underscore character on a Selectric type ball. Dropping a type ball would often break off the indexing tooth under the underscore or dash character, rendering the ball useless. (Photo by author.) |

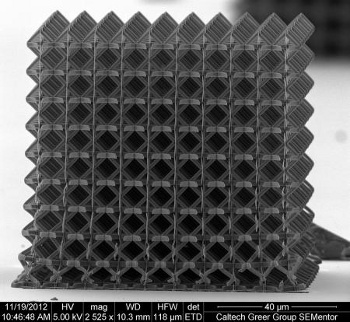

σf√a ≈ Cwhere σf is the stress at fracture, a is the notch length, and C is a constant that depends on the energy required to create two new surfaces at each side of the fracture. Griffith's work was ranked in the top fifty of the greatest materials moments by the The Minerals, Metals & Materials Society (TMS) in 2007.[2] Scientists at the California Institute of Technology (Pasadena, California), the Jet Propulsion Laboratory (Pasadena, California), and Caltech's Kavli Nanoscience Institute have sharpened their nano pencils, and they've created nanoscale truss-like structures that mimic the siliceous skeletons of microscopic organisms such as diatoms and radiolaria.[3-5] The lightweight, porous skeletons of these organisms have remarkably higher strength than man-made structures of the same composition. The Caltech research team fabricated hollow ceramic scaffolds of the same dimension and hierarchical structure of these skeletons, relying on Griffith's prediction that the smaller pieces would have high strength when combined. The fabricated structures (see image) attained a compressive strength of 1.75 GPa without failure, even after many deformation cycles, and their experiments showed that this approach can be used to create lightweight, damage-tolerant, engineering materials.[3] bio-inspired counterparts, are more than 85% air.[4] The structure is comprised of repeating octahedral unit cells, which mimics the periodic lattice structure of diatoms.[4] Says Julia R. Greer, professor of materials science and mechanics at Caltech and project leader,

"Inspired, in part, by hard biological materials and by earlier work... we designed architectures with building blocks that are less than five microns long, meaning that they are not resolvable by the human eye... Constructing these architectures out of materials with nanometer dimensions has enabled us to decouple the materials' strength from their density and to fabricate so-called structural metamaterials which are very stiff yet extremely lightweight."[4]To fabricate these structures, the research team formed a three-dimensional polymer lattice by two-photon lithography. This polymer lattice was coated with thin layers of titanium nitride (TiN), and the polymer core was removed, leaving the TiN ceramic nanolattice. The hollow struts had wall thickness of 75 nanometers or less.[4] The research team has fabricated structures as large as a one-millimeter cube.[4] They've also substituted gold for the TiN. Says Greer, "Basically, once you've created the scaffold, you can use whatever technique will allow you to deposit a uniform layer of material on top of it."[4] Such bio-inspired structures have great potential. Nanoscale metals can be fifty times stronger than their bulk, and the mechanical character of some amorphous materials changes from brittle to ductile. This process can be used to produce mechanically strong nanoscale batteries and implantable biomedical devices.[4] The research was funded by DARPA's Materials with Controlled Microstructural Architecture program, and the Army Research Office.[4]

References:

- A.A. Griffith, A. A. (1921), "The phenomena of rupture and flow in solids," Philosophical Transactions of the Royal Society of London, vol. A221 (1921), pp. 163–198. Available here, also.

- The Greatest Moments in Materials Science and Engineering, The Top 50 Moments in History, The Minerals, Metals & Materials Society (TMS).

- Dongchan Jang, Lucas R. Meza, Frank Greer and Julia R. Greer, "Fabrication and deformation of three-dimensional hollow ceramic nanostructures," Nature Materials, September 1, 2013, doi:10.1038/nmat3738.

- Kimm Fesenmaier, "Made-to-Order Materials - Caltech engineers focus on the nano to create strong, lightweight materials," California Institute of Technology Press Release, September 5, 2013

- Supplementary video for ref. 1. Uniaxial compression test on a unit cell of the octahedral titanium nitride nanotruss at five times the actual speed.

- The Greatest Moments in Materials Science and Engineering, The Top 50 Moments in History, The Minerals, Metals & Materials Society (TMS).