Superhydrophobic Anti-Glare Glass

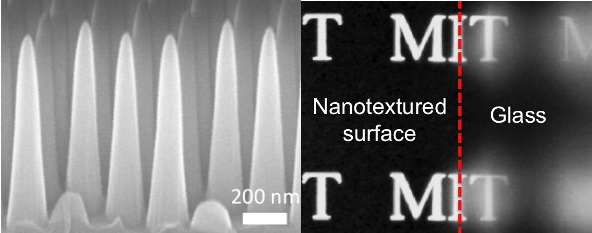

May 2, 2012 Glass is a versatile and inexpensive material with many admirable physical and chemical properties. Although plastic is the material of our age,[1] a cursory survey of my pantry reveals many glass food containers. The glass we've looked through most often is the windshield of our automobile, and that observation reveals some of the opportunities for improving window glass. These windows are dirty, and they produce distracting glare. Glass technology has had a resurgence in recent years with the strict requirements of display glass. This started with the replacement of nearly all cathode ray tubes, for both entertainment displays and computer displays, with flat panel displays, and it continued with some special requirements for cellphones and tablet computers. I wrote about the glass used in the Apple iPhone, "Gorilla Glass," in a previous article (Gorilla Glass, August 11, 2010). This might not be the best example, since the iPhone glass is based on some very old technology.[2] A team of engineers from the Massachusetts Institute of Technology has addressed some problems with glass by a surface microstructuring process to simultaneously reduce glare and improve surface cleanliness.[3-6] They used conical nanotextures to give the glass surface a large topographic roughness (see figure). When you're producing nanoscale features covering a large area, there are quite a few processing challenges. You need to maintain the nanoscale features of the structures and their periodicity with very few defects. The immediate benefit of the nanostructure is that the tapered surface material presents a perfect refractive index gradient that matches the refractive index of the glass to air, thereby minimizing reflection (glare). Optical transmission exceeding 98% was achieved over a wide range of wavelengths and incident angles, which means that the reflection was only 2%. |

| Left image - The surface structure of the MIT glass. The aspect ratio of the cones is about five-to-one. Right image - The anti-fogging property of the MIT glass that results from the surface superhydrophobicity. (MIT images by Hyungryul Choi and Kyoo-Chul Park).[3] |

| Illustration of a lotus leaf surface. (Still image from an animation by William Thielicke, via Wikimedia Commons). |

| A water droplet bouncing off an MIT nanostructured glass surface. (Still images from a YouTube video.[6] |

References:

- Remember, for example, this famous scene from The Graduate (1967, Mike Nichols, Director):

Mr. McGuire: I just want to say one word to you. Just one word.

Benjamin: Yes, sir.

Mr. McGuire: Are you listening?

Benjamin: Yes, I am.

Mr. McGuire: Plastics.- David C. Boyd, "Sodium Aluminosilicate Glass Article Strengthened by a Surface Compressive Stress Layer," U.S. Patent No. 3,778,335 (December 11, 1973).

- David L. Chandler, "Through a glass, clearly - MIT researchers find a way to make glass that's anti-fogging, self-cleaning and free of glare," MIT News Office Press Release, April 26, 2012.

- Kyoo-Chul Park, Hyungryul J. Choi, Chih-Hao Chang, Robert E. Cohen, Gareth H. McKinley and George Barbastathis, "Nanotextured Silica Surfaces with Robust Super-Hydrophobicity and Omnidirectional Broadband Super-Transmissivity," ACS Nano Just Accepted Manuscript, April 8, 2012, DOI: 10.1021/nn301112t.

- Dave Smith, "MIT Researchers Invent 'Perfect Glass'," International Business Times, April 26, 2012

- Fog-free glass, MIT News Office, YouTube video, April 26, 2012.

- David C. Boyd, "Sodium Aluminosilicate Glass Article Strengthened by a Surface Compressive Stress Layer," U.S. Patent No. 3,778,335 (December 11, 1973).