Super Condensing Surfaces

November 9, 2012 Autumn is half over, so winter is not that far away. It's officially winter only after the winter solstice (sometimes called the December solstice). It occurs this year on December 21 at 11:12 UTC (6:12 AM EST), but we usually see snow in my area before that date. That day is the shortest day of the year for the denizens of the northern hemisphere. Since our calendar, because of leap years, is just an approximation of what's happening astronomically, the winter solstice can happen on dates from December 20-23. As we learned in elementary school, we have seasons because the Earth's rotational axis is tilted with respect to its orbital plane. At the winter solstice, this 23.5° tilt puts north latitudes of 66.5° and greater (the Arctic Circle) in day-long darkness, and south latitudes of 66.5° and greater (the Antarctic Circle) in day-long daylight. Degrees of angle are interesting, but it's degrees of temperature that most concern me at this time of year. New Jersey summers are very nice, as the tomatoes will attest, but the winters can be somewhat difficult. Ice and snow are major problems for people living in these higher latitudes, especially for a society that spends an inordinate fraction of its wealth on automobiles, automotive fuel, insurance and roads. In a recent article (Icing-Resistant Surfaces, August 8, 2012, written in sunnier times, I wrote about research on the development of icing-resistant surfaces by a team of scientists at Harvard's School of Engineering and Applied Sciences.[1-2] Although nanoscale-modified surfaces are superhydrophobic (water repellent), since the contact angle of droplets is very large (>150°), they are surprisingly not icing resistant. The Harvard solution was to infuse superhydrophobic surfaces with a water-immiscible liquid. This method, which they call SLIPS, for "Slippery Liquid Infused Porous Surfaces," presents a molecularly flat liquid interface to oncoming water. The nanostructured surface holds the liquid in place, and water droplets, frost and ice can't adhere to the liquid, so they slide off.[1] Now, a crosstown Boston team from MIT's Department of Mechanical Engineering has applied similarly lubricated, nanotextured surfaces to improve water condensation in condenser systems used for a variety of applications.[3-6] Condensers are ubiquitous. About eighty percent of powerplants use condensers to turn steam back to liquid water after it's done its job of powering turbine-generators. They're also a principal component of desalination plants, condensing fresh water from heated brack.[3] | A typical steam condenser system. Steam condenses on the interior pipes. Illustration by Milton Beychok (modified), via Wikimedia Commons). |

|

| Still from a YouTube video. |

References:

- Michael Patrick Rutter and Twig Mowatt, "A new spin on antifreeze - Researchers create ultra slippery anti-ice and anti-frost surfaces," Harvard School of Engineering and Applied Sciences Press Release, June 11, 2012.

- Philseok Kim, Tak-Sing Wong, Jack Alvarenga, Michael J. Kreder, Wilmer E. Adorno-Martinez and Joanna Aizenberg, "Liquid-Infused Nanostructured Surfaces with Extreme Anti-Ice and Anti-Frost Performance," ACS Nano, vol. 6, no. 8 (August 28, 2012), pp. 6569-6577.

- David L. Chandler, "A better way to shed water," MIT Press Release, October 22, 2012.

- Sushant Anand, Adam T. Paxson, Rajeev Dhiman, J. David Smith and Kripa K. Varanasi, "Enhanced Condensation on Lubricant-Impregnated Nanotextured Surfaces," ACS Nano, Article ASAP, DOI: 10.1021/nn303867y, October 2, 2012.

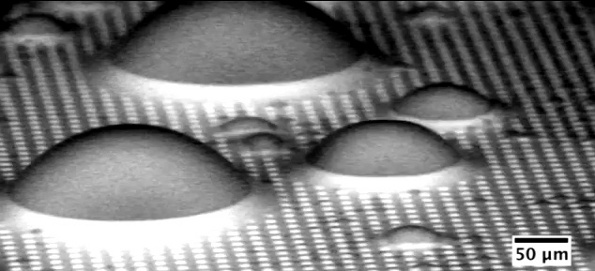

- Konrad Rykaczewski, Trevan Landin, Marlon L. Walker, John Henry J. Scott and Kripa K. Varanasi, "Direct Imaging of Complex Nano- to Microscale Interfaces Involving Solid, Liquid, and Gas Phases," ACS Nano, Article ASAP, DOI: 10.1021/nn304250e, September 28, 2012.

- Enhanced Condensation on Lubricant-Impregnated Nanotextured Surfaces, YouTube Video, October 22, 2012.

- Philseok Kim, Tak-Sing Wong, Jack Alvarenga, Michael J. Kreder, Wilmer E. Adorno-Martinez and Joanna Aizenberg, "Liquid-Infused Nanostructured Surfaces with Extreme Anti-Ice and Anti-Frost Performance," ACS Nano, vol. 6, no. 8 (August 28, 2012), pp. 6569-6577.