Bubbles and Boiling

September 24, 2012 Every chemist has used boiling stones. These are small, irregularly-shaped bits of inert material, and they are added to liquids to act as nucleation sites for bubbles during boiling. These provide a more uniform boiling of a liquid, and they prevent the large, burping bubbles that expel liquid from beakers. In alchemical times, these were probably real stones, but now they're just ceramic pieces. It's important, however, to ensure their inertness, especially in the high temperatures at which most boiling occurs. I'm sure that some chemists have been unable to reproduce some experiments, since they didn't consider the possible catalytic action of metals in the ceramics. | There's an old joke about the newlywed who was such a bad cook, she didn't know how to boil water. The joke is still politically correct if we just say, "newlywed," and don't assume it's the woman. (Photograph via Wikimedia Commons). |

References:

- Erin White, "Boiling Water Without Bubbles - Researchers engineer special surface, allowing water to boil without producing bubbles," Northwestern University Press Release, September 13, 2012.

- Ivan U. Vakarelski, Neelesh A. Patankar, Jeremy O. Marston, Derek Y. C. Chan and Sigurdur T. Thoroddsen, "Stabilization of Leidenfrost vapour layer by textured superhydrophobic surfaces," Nature, vol. 489, no. 7415 (September 13, 2012), pp. 274-277.

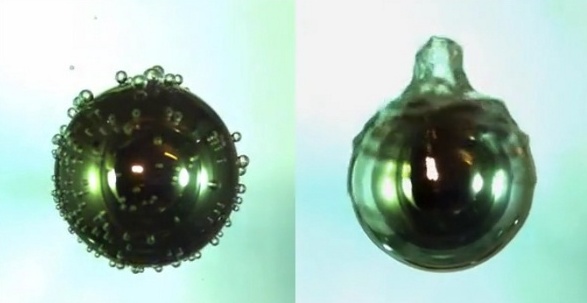

- Supplementary movie for ref. 2. Steel cylinder heater with a superhydrophobic surface immersed in 100 °C water.

- Ivan U. Vakarelski, Neelesh A. Patankar, Jeremy O. Marston, Derek Y. C. Chan and Sigurdur T. Thoroddsen, "Stabilization of Leidenfrost vapour layer by textured superhydrophobic surfaces," Nature, vol. 489, no. 7415 (September 13, 2012), pp. 274-277.